TS: Matthew Boyd, you are the Vice President of Sales for Parker Fasteners. How long have you been with Parker and how did you end up with the company?

Matt: Thank you, TS, for the opportunity. I have been with Parker Fasteners for eight years, September of this year. Previous to Parker Fasteners, I spent almost 13 years in distribution, working the last four years as a District Manager for the Fastenal Company. When Parker Fasteners started to call on me as a local customer, I was intrigued by Parker Fasteners. Not many fastener manufacturers are starting from scratch these days, so my interest started from that point. Overall, making the transition from distribution to manufacturing was a challenge, however I would do it again in a heartbeat!

TS: Please share with us a little bit of the history of Parker Fasteners

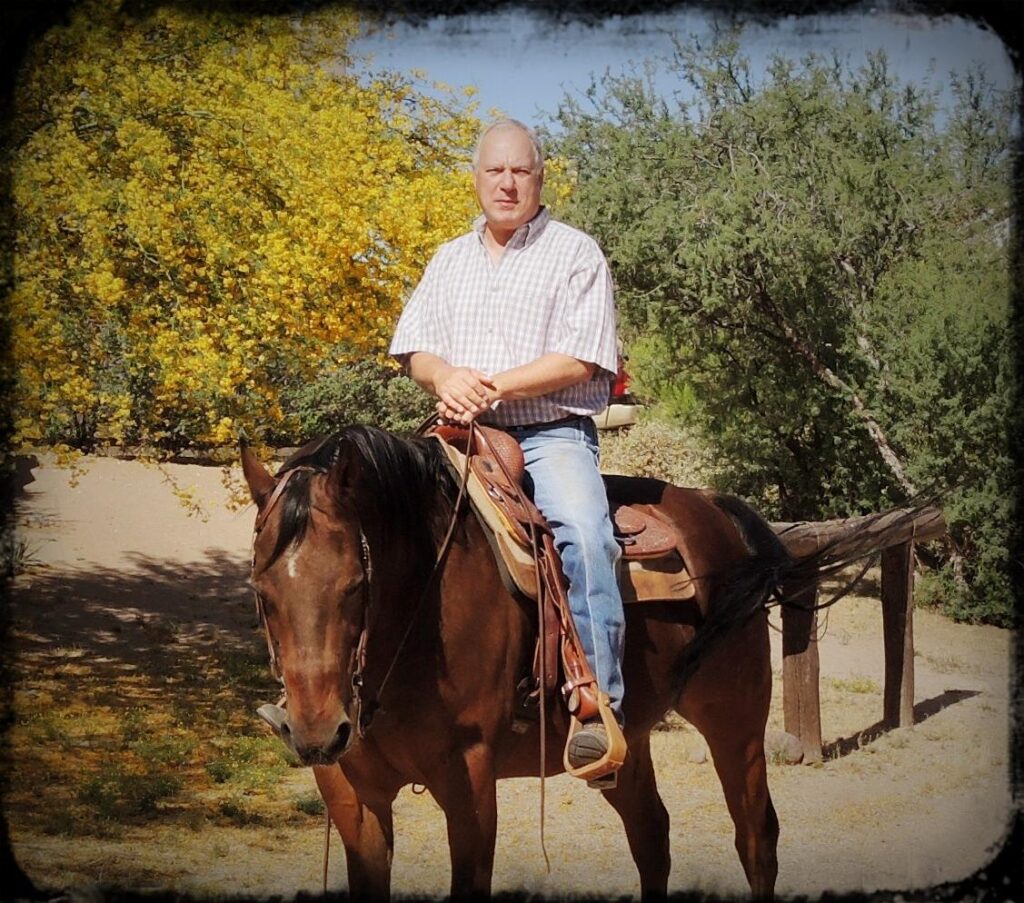

Matt: Parker Fasteners was founded by Robert Parker in May of 2012. With over 20 years of experience in fastener manufacturing, Robert brought instant creditability and know-how to the operation. I call it the “Original Fifteen” of employees who started with Robert in the beginning. This group of employees have shown grit and the willingness to take a chance together, with Robert’s dream of creating a company that values employees and takes care of its customers at the highest levels possible. This philosophy has set myself and the rest of our sales team up for long-term success in the market.

TS: Your company slogan is – “Parker Fasteners – Forging the Future”. You’ve got it printed on t-shirts, it is on your website. Why is that slogan a good fit for your company? What are you guys trying to say to the fastener industry?

Matt: In the beginning, many folks in the industry didn’t take us seriously. It was almost like our age in the industry was working against us. After our second year at the Fasteners Show in Vegas, walking down the aisle to our booth towards the back of the show, Robert mentioned to me that we were “Forging The Future through Quality Products and Customer Service.” I quickly took out my phone and took notes on what he had just said, so unassuming. Once we made it back into the office, we revisited the thought he had and boiled it down to “Forging The Future.” The slogan is the rally cry to our employees, customers and vendors today. For employees, the company wants to reinvest and give back for all of the hard work and dedication that they make daily. For customers, the company is continuing to reinvest in itself to improve the offering, so each order that is made to Parker Fasteners is an investment in everyone’s future. Concerning our vendors, making sure they understand our plans to growth is key to our success. So, as you can see, our company’s aggressive approach is communicated throughout the business.

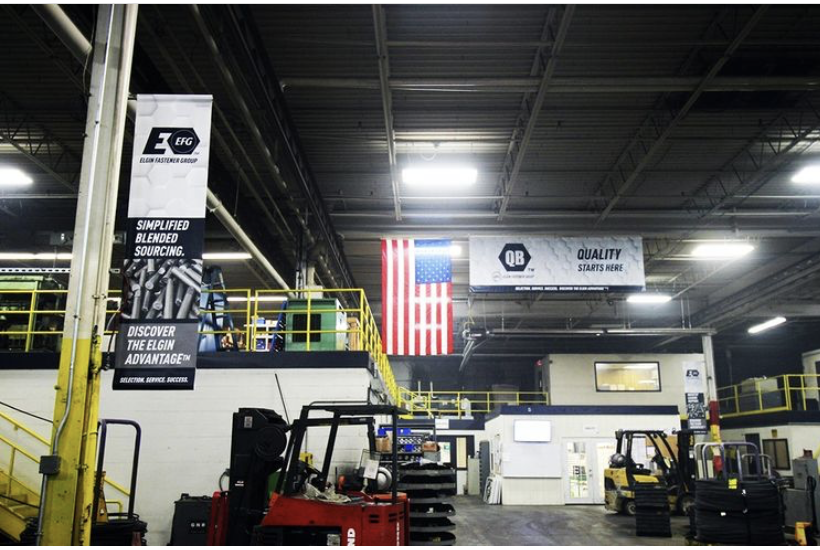

TS: You moved into a new manufacturing facility during 2020, and during Covid. Tell us about the new facility.

Matt: Can’t say enough about our new facility, located in Buckeye, Arizona. It was a challenge moving in April/May of 2020, however with all of the efforts that we put in, we were very careful and completed the move without any COVID related issues. Operating from 66,000 square feet, in one building, 100% climate controlled has made all the difference. Our team has done a wonderful job of laying out the facility, organizing it and we are setup for years of growth. We are also sitting on 10 acres in total, so we have another 100,000 of square feet of future expansion. Our employees have responded very well and we have almost doubled our production since we moved. If anyone in the industry is interested in taking a tour, please reach out to me and I would be happy to schedule it.

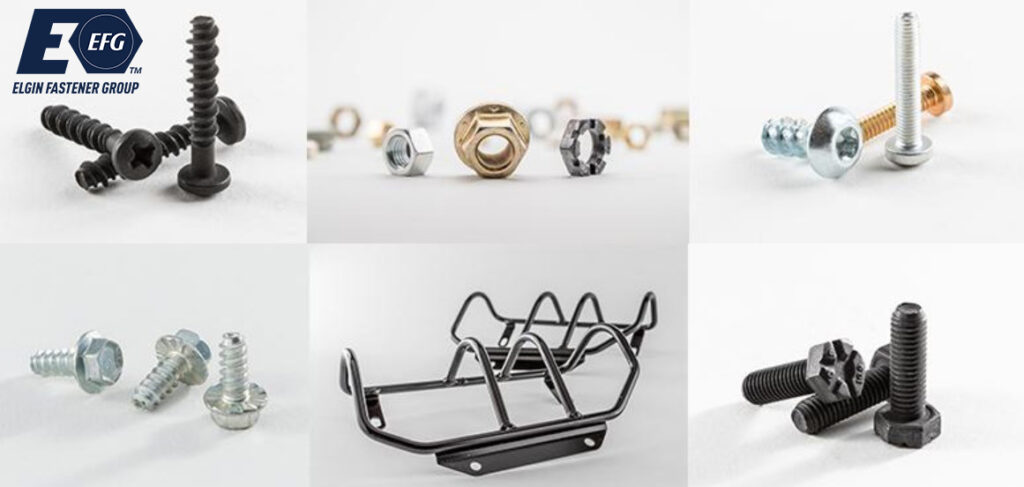

TS: While Parker Fasteners has a wide range of capabilities, you really seem to concentrate on socket head cap screws and mostly product made from stainless steel. But you tell me – what products do you consider to be in the Parker “wheelhouse”? What markets do you target and serve?

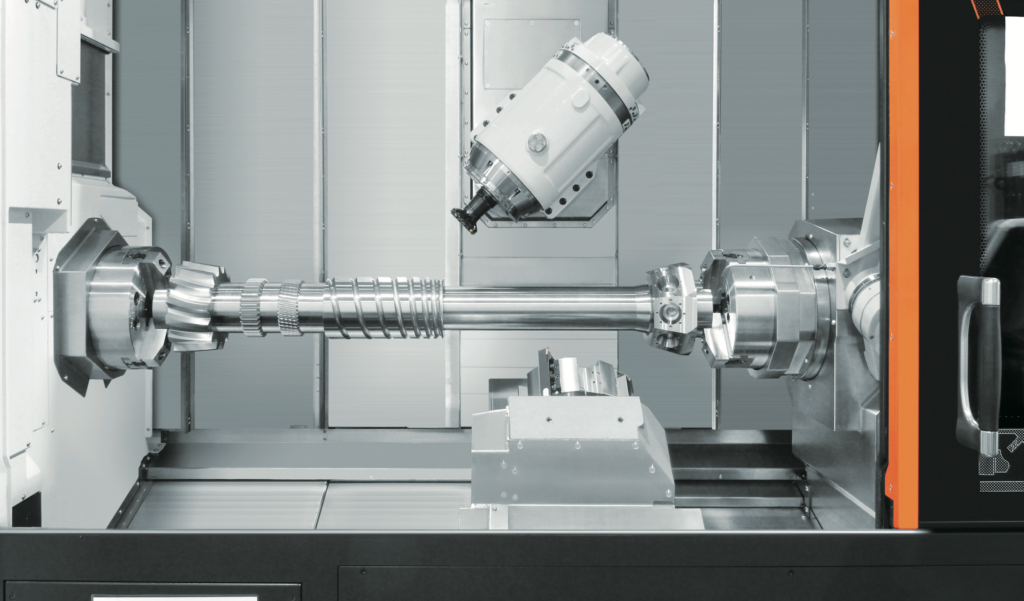

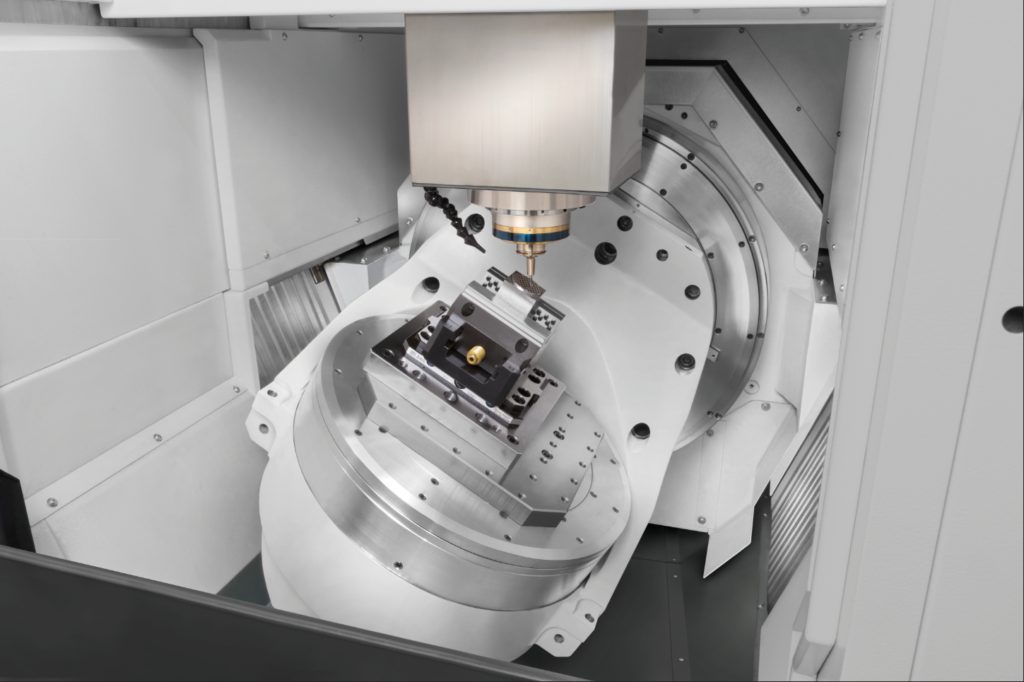

Matt: Yes, Stainless Steel and A286 sockets are over half of our business today. Being so close to California, we are able to rely on our vendors to keep us competitive on those types of raw material and outside services that are required for socket head cap screws. With that product offering, we also offer button, flats and related products that require the deep recess. Other materials that we offer are alloy, monel, brass and nitronic 60. What the industry also needs to be aware of, is that we offer the longest, precision cold die cold heading capabilities in the country. Capable of producing 12” from under the head, this is a unique product offering for domestic manufacturing. We also offer expanded products for the military and aerospace markets including per print specials.

TS: The company could have moved in many directions, so how did the company come to concentrate on those products and markets?

Matt: Starting nine years ago, we were looking to fulfill any needs in the open marketplace. We quickly found our niche’ in the socket drive business, just by listening to our customers. Being diversified in as many different markets is an company goal. We currently service many markets domestically and globally. As a growth company, it is always best to engage us to see if a part would be a good fit for our equipment or not. We are always willing to recommend other proven manufactures who we know if the part isn’t a good fit.

TS: In the Midwest it is very difficult to hire machinists and individuals who can operate heading equipment. Is it the same in Arizona? What are you doing to recruit and train?

Matt: Yes, the labor market is very unique right now. In past years, we would look for experienced labor from other states to recruit, and we still do today. However, we have found success from developing our own internal training plan for candidates without hands on experience. This has proven track record for the company. Regarding retention, when employees see that a company is investing in them and their future, they are most likely to stay and match that investment with their own personal goals and efforts. This has been our strategy over the past two years and it has given us the talent required to grow our business.

TS: What is in store for Parker Fastener in the upcoming years?

Matt: Working smarter, not harder is the mantra that we have used since our move into our new facility. To explain further, we have invested heavily in our ERP System, Quoting Software, equipment and our people. Staying competitive in the marketplace, providing reasonable lead times and engaging our customers to meet their needs, is what we are all about. The reinvestment outlook that we have will continue our company’s efforts to “Forge The Future!”

TS: What are a couple things people do not know about Parker Fastener or its people that you want to tell the fastener industry?

Matt: The culture at Parker Fasteners is one of a kind. From the way that we engage our customers, employees and vendors we are constantly looking to find the win-win for everyone. It’s one of a kind effort that we put into our business daily, and it’s our goal to improve each day.

Note from TS:

I have a regular column in Fastener Technology International (FTI) magazine, called 10 Minutes with the Traveling Salesman, which can be read online at www.fastenertech.com. Subscriptions to FTI, print and digital editions, are free-of-charge for fastener manufacturers, distributors and users as well as suppliers to the industry.”