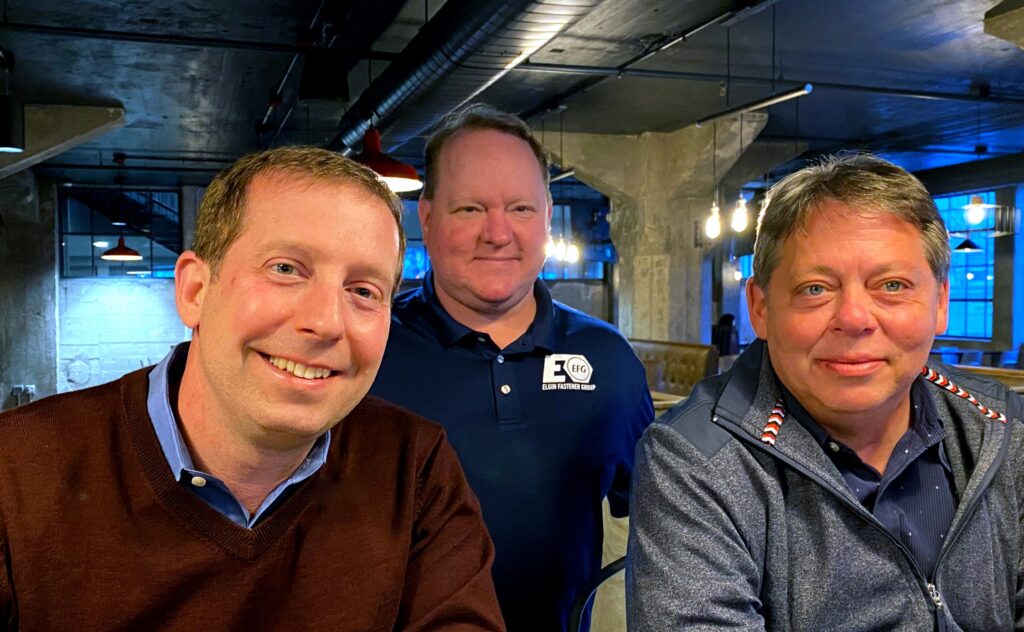

TS: OK, I have got a lot of ground I’d like to cover with this interview, but let’s get you properly introduced to our readers before we get going. You are Joe Kochan from the Elgin Fastener Group. What is your exact title at Elgin?

Joe: I am the Vice President/General Manager

TS: Now, what do you really do at Elgin?

Joe: I am directly responsible for the operations, customer service, and inside sales of the company. As a key leader in the company I work with the rest of the Leadership Team, comprised of Brian Nadel, CEO, Dan Lawrence, CFO, Jason Swatek, VP of Supply Chain, and Joe Shoemaker, VP of Business Development to set the strategic direction and how we will deploy or achieve that strategy on an annual basis. It’s a great position to be in because I get to work directly with people like the CEO and also with the customers as well as the people making the product in the facilities.

TS: And before working with Elgin you did have some history in the fastener industry, correct?

Joe: I had the opportunity of working as a consultant then as an employee of Maclean Fogg for a couple years focused in Supply Chain. It was a great introduction to the fastener industry through a company that now has close to 100 years in the business. I have been able to take the many experiences I collected there and carry them forward to EFG. I’ll always look back at my fastener introduction, the experience, and the people there quite fondly.

TS: In addition to working in the fastener industry what have been some of your other work experiences?

Joe: Many people do not know that I actually started my career on the shop floor as a third shift press operator quickly shifting to welding at a Dana, Inc facility in Alabama. My first two professional milestones were achieved there. First by getting my blue shirt meaning I was hired as an employee. I started as a Temp. And then moving into the office (into accounting).

I’ve had opportunities of being in leadership roles such as Plant Manager, Director of Supply Chain, Director of Operations, General Manager, and VP of Global Operations. I’ve built, shipped, or sold various products in automotive, heavy truck, general industrial, and even technology/IoT.

While there is an experience or two I’ve left out, I can truly say I have done some pretty cool things and met many amazing people.

TS: Great, that is a well rounded background. So, let’s jump into the discussion about Elgin Fastener. We can start with the easy stuff – there are several different business units, what does each one do?

Joe: There’s no short answer but I’ll at least try to be concise. Here are the facilities:

The Elgin Fastener Group is made up of 8 facilities and 9 brands:

- Telefast in Berea, OH manufacturing internally threaded fasteners sizes from M6 up to M22

- Quality Bolt in Brecksville, OH manufacturing larger diameter and lengths pins and externally threaded product ranging from M10 to M27

- Ohio Rod in Versailles, IN producing longer externally threaded fasteners and threaded rod as long as 86 inches

- Best Metals in Osgood, IN. Best Metals is one of our best kept secrets not only providing Ohio Rod with plating serves but also a few strategic commercial partners as well.

- Leland Powell in Martin, TN manufacturing high volumes of rivets and externally threaded product ranging from M3.5 to 12mm.

- Holbrook in Wheeling, IL supporting customers with a full range of fastener related product with manufacturing capability from M2 to 12mm licensed externally threaded products.

- Rockford Fastener in Rockford, IL, acquired early 2020, capable of producing a full range of rivets, studs, and externally threaded fasteners in M3 to 12mm sizes.

- Northern Wire in Merrill, WI is EFG’s wire form operation able to produce product from .125 to .750 “ in diameter and ½ “ to 12’ long.

TS: Several of your plants are based in the Cleveland area so I also know that you shut down a plant last year, the Euclid plant. That could not have been an easy decision. What was behind that decision?

Joe: It’s never an easy decision to disperse a facility’s capabilities, assets, and products to other parts of a company. The most difficult part of those decisions is appreciating the impact to the people that started, grew, and were a part of that business. Fortunately, EFG had the ability to give people plenty of time to decide if they wanted to take advantage of moving to another facility or make a different decision regarding their future. We will always be grateful to those people.

Regarding the business decision, again it was not easy. Chandler Products has a lengthy and successful history in the marketplace that we wanted to preserve while becoming more effective in serving our customers and partners. When we looked at our footprint, capabilities, and ability to leverage talent it was apparent we could move the Chandler product line from Euclid, OH to Quality Bolt and Rockford Fastener. In doing so were able to keep the Chandler products alive, running, and growing while improving our effectiveness in customer service exiting the Euclid, OH facility.

TS: Just one final little observation – when you talk about the different companies. Northern Wire and the wire forms offerings kind of stand out from the others as they are not threaded and do not fall into the “commodity product” category. Tell me a bit more about Northern Wire.

Joe: Over the course of my past lives I have come to enjoy a quick tag question when I talk to people, “Wanna by a whatever?” At EFG Northern Wire has become the product I often use. So TS, “Wanna buy a wire form?”

When I do ask that question the usual follow-up is, “What is a wire form?” Then I get to describe it and people usually quickly understand. One thing to clarify though. Many of our wire forms are actually threaded. Didn’t know that eh? But yes it’s true.

While wire forms might not be thought of or included in the fastener commodity it is quite complementary to what we do and sell as EFG. If you think about it, and the fact that they are often threaded or have a pierced hole, fasteners are used to secure it in place.

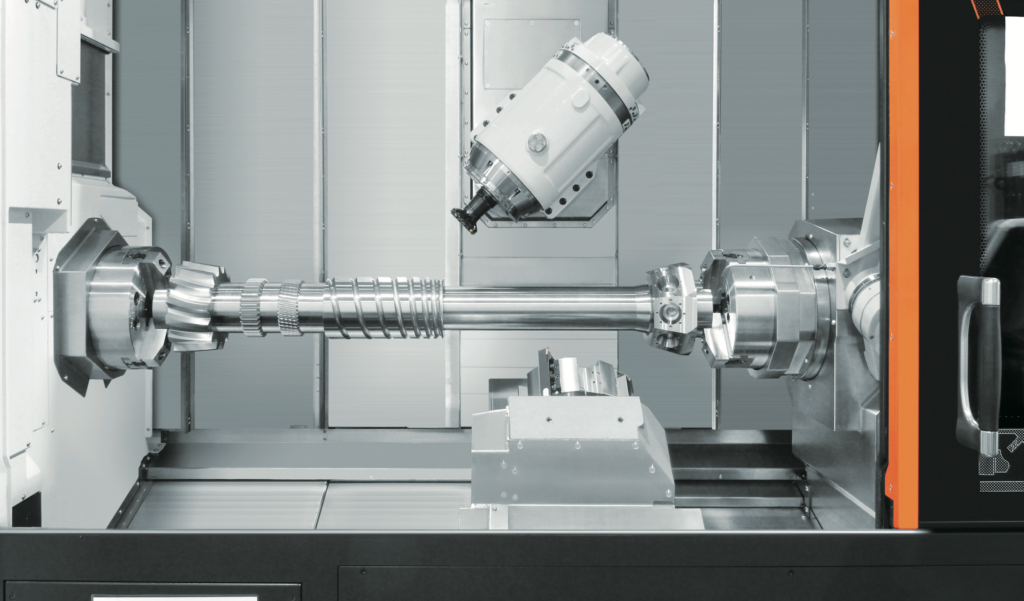

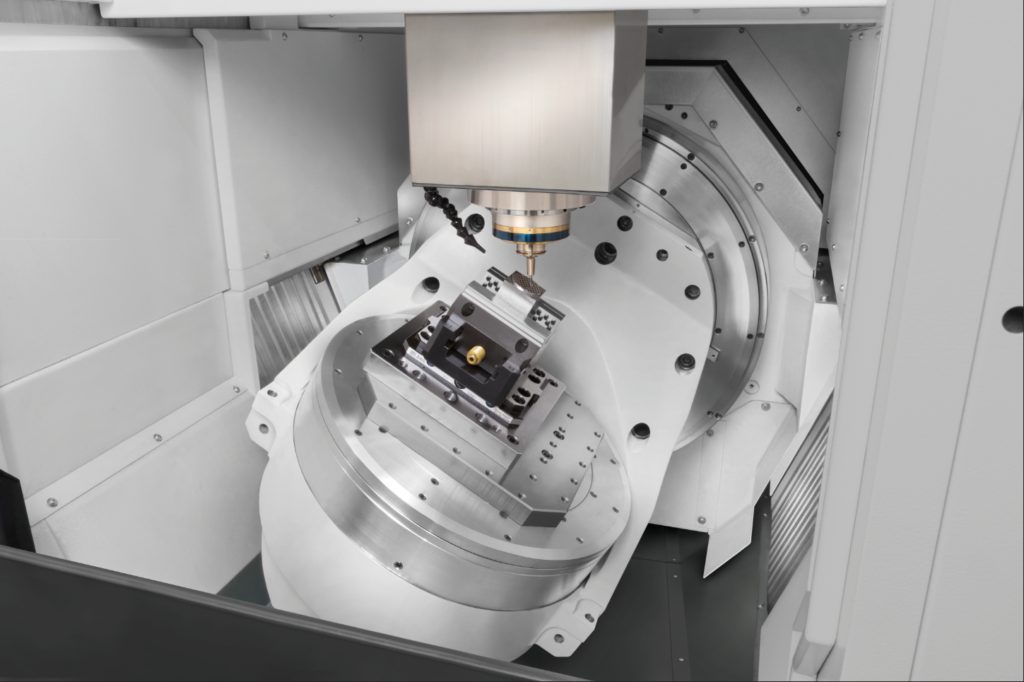

Northern Wire is a really cool product line with mostly unique processes as compared to the rest of EFG. Even the threading process done on a CNC machining center (not cut but rolled). They are operating 10 to 600 ton presses (similar to what I ran early in my career), CNC wire benders (similar to the CNC tube benders in the first facility I managed), and many other processes. We are largely a JIT supplier for most of the customers we serve largely focused, for now, on the Lawn and Garden market.

Like many industries and facilities they are impacted by today’s common outside forces that most are. But they are overcoming these challenges quite well and remain an important and growing part of our growth plan. When we think about the EFG Advantage and selling multiple products to a customer, Northern Wire expands that opportunity.

By the way, “Did you want to buy a wire form TS?”

TS: Not at this moment but something might come across my desk later today. But you’re in my head now.

I have been in the fastener industry nearly 35 years and seen a lot of changes. Over the years there have been a lot of companies that have come and gone and many that have changed due to mergers and acquisitions. This is true both on the distributor side and on the supplier side of the business. Elgin is owned by private equity. How do you retain the history and brand recognition as you merge companies together?

Joe: This is a great question. As you know, EFG is comprised of companies that were either family or privately owned and yes each with a distinct culture. When companies are put together like EFG has been, there are decisions to be made around identify. “Do acquired companies get rolled into the acquirer without regards to its history?” “Are companies left alone to operate independently as though nothing changed?” etc, etc.

At EFG we have decided it is important for each facility or brand to both maintain their identity as well as feel they have an advantage of being part of a larger company. You will notice on our website and in our marketing information that each brand starts with the name of that brand with EFG beneath or following it rather that EFG leading.

Each business that has been brought into EFG was acquired for a purpose and with the knowledge they were bringing a certain value to the company we didn’t have. I can tell you after being part of this great company for almost two years it is not easy. The two things we will continue to remind ourselves to do as we continue our growth are do not lose site of why a business was acquired and when you think you are listening to your people and partners – listen more.

TS: What are the benefits of private equity and what are the challenges?

Joe: I have enjoyed working throughout my career in US and global public companies, family owned, and private equity sponsored companies. While I would say each structure does have various and ‘predictable’ nuances each is really about the people you work with and the culture you work in. Audax has been a tremendously supportive partner and sponsor to EFG. Our continued success and growth is a clear reflection of their buy and build approach.

So back to your question, benefits and challenges. I would say the primary benefit is having a strong, clear, and transparent partnership and access to people that are there to support the business whether in guidance or investing in growth and the future. When it comes to challenges other than day to day things that any business experiences the benefit I gave is a very high hurdle for any challenge to overcome. I truly believe that …

TS: Elgin is very active on social media. The “Elgin Advantage™” in often mentioned in promotional material. What is the “Elgin Advantage™ “?

Joe: Over the last couple years, we have come to appreciate the work our VP of Marketing, Joe Shoemaker (Shoe), has done on social media more and more. I’m not sure how he comes up with his ideas but it is definitely fun to be a part of and to wait and watch for his, at least, daily posts. You never know, I was our first, he is looking for the next bobble head now … TS??? Haha!

When it comes to the EFG Advantage there is a lot to those two words. When I first joined EFG our structure comprised of two divisions, Rod, Nut, and Bolt with four facilities/brands and Wire and Screw with three facilities/brands. Within those two divisions each facility or brand served their customers differently. This is what people would typically refer to as a House of Brands. While there is nothing wrong with that approach, we started asking ourselves questions like “Does this disconnection allow us to serve our customers the way they deserve?” and, well TS, we are here to grow so the next one was “Are we leveraging and selling our products and capabilities across all EFG customers?” When our internal answers to these questions were ‘no’ we searched for and received the same response through the voice of the customer.

We listened and learned and that propelled us to begin the transition from a being a House of Brands to a Branded House. The ‘idea’ of naming it the Elgin Advantage™ came from Joe Shoe. While we could take a whole 10 Minute Interview to focus on this it can really be boiled down to three key themes of Service, Selection and Success. We have a unique collection of capabilities for our customers and employees, so we needed to condense these into something easily digestible when communicated internally and to our markets. This led us to three key concepts.

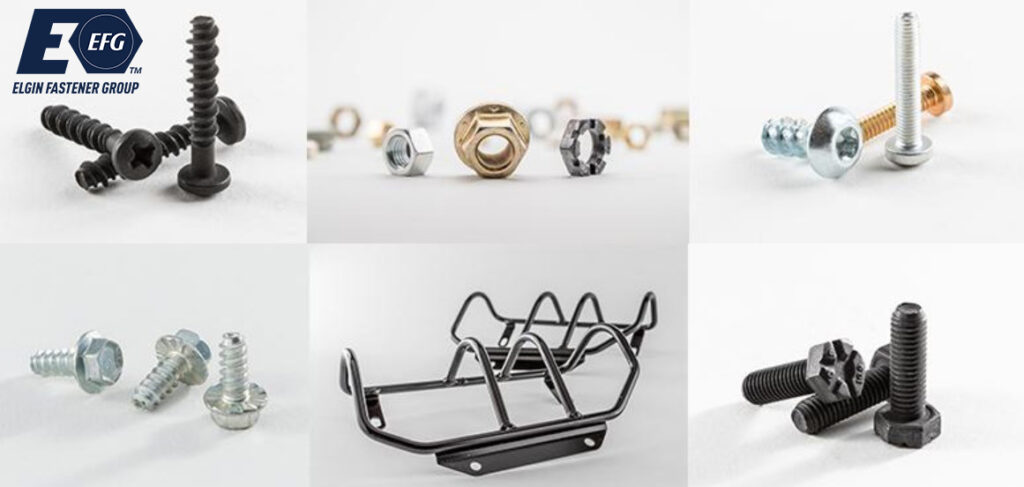

The first is ‘Selection’. To our customers, we offer the largest selection of specialty fasteners, licensed fasteners, and wire forms from a single source. To our employees, our scale provides opportunities for relocation and advancement. There have been examples of team members advancing in roles or even taking on new roles within the company or at a different facility.

Next is ‘Service’. We serve our customers with high quality products, which is foundational for us. Our Blended Sourcing capabilities provides a low-cost solution for high volume runners while backing up demand spikes with local manufacturing, quality control and support. Internally, we serve our teams through employee development programs and making investments in our facilities, processes, and tools for growth.

Finally, there’s ‘Success’. As our customers enjoy success resulting from our partnership, we will grow though customer loyalty, satisfaction, and increased brand penetration. Internally, we will be successful by developing talent and being viewed as an employer of choice.

With the three key concepts in place, we just needed a ‘call to action’ which resulted in the tag line you have seen in our advertising and it has served us well.

TS: I agree and I admire how active Elgin is involved in social media including LinkedIn, Twitter, Instagram and probably others I do not see as often. Have you seen positive, measurable results from that activity?

Joe: We definitely have. I spoke about Joe Shoe earlier and the super cool stuff he is doing.

From a measurable point, our marketing exposure has significantly increased. Whether it is LinkedIn followers, connections, likes, shares, etc. all are extremely favorable. The number of qualified leads, where people have followed us through to the website for quotes and requests, have increased in the hundreds of percent improvement. Just recently we hit 4,500 followers on LinkedIn!

Social media is going to continue playing an important and growing part in sharing with our people, our customers, and the industry what the Elgin Advantage can do for them.

TS: Combining companies together is not always easy or without some setbacks. Yet Elgin seems to have maintained and grown its business. To what do you attribute the growth you have experienced?

Joe: Without hesitancy or a doubt, it is the people of EFG. Without them there is no Elgin Advantage. EFG has grown by acquisition and organic sales because our people care about each other and serving the customer. When people started their careers I’m pretty sure it wasn’t because they grew up wanting to make nuts or bolts. It was first to take care of themselves, then their families, and then, of course, their team members and customers. We grow through their dedication, caring and desire to build and sell the best product out there.

Now, from a product and capability perspective, we offer the most complete fastener portfolio in the industry. Whether bolts, screws, studs, rod, rivets, nuts, wire forms, and everything in between we offer it. Do we have challenges, sure we do and we don’t avoid acknowledging them. Combining companies and cultures while enjoying significant growth is not a simple task. That said and getting back to the people, we have extremely strong people that care about what they do and understand the need for transparency and the need to be head over heels in serving the customer.

As we focus and improve our ability to serve the industry through the Elgin Advantage, offering our products and solutions as a whole rather than individually, our growth will continue to accelerate.

TS: Now that you have a few years under your belt at Elgin, along with your previous fastener experience, what do you find unique about the fastener industry that distinguishes it from other industries you have been involved in?

Joe: That’s a great question.

I don’t think people walking down the fastener aisle at their local hardware store really understand the amount of engineering and quality control it takes to make that ‘simple’ wood screw. Then you take a complex fastener for a more difficult application like automotive, aerospace, or construction and it’s a level or three greater in engineering. And with so many products and types of fasteners it boggles my mind at times.

From a manufacturing perspective there are so many methods that can be required to produce a fastener. Cold heading, warm heading, hot forging, machining, stamping, countless secondary operations, the list goes on all while making thousands, hundreds of thousands, or millions of the same repeatable part. All this requires highly skilled people across the entire business from the plant floor to the engineering and quality department and the sales desk.

It is also a very close knit community where most people either know each other or know of each other. So many of the fastener houses in the US were started as small scale facilities and grew over time with a competitive but close comradery I have not seen in other industries.

This industry safely ‘fastens’ the world together and it’s fun to be a part of it.

TS: EFG is made up of several domestic manufacturing companies and there are certain challenges that are always faced by domestic manufacturers including hiring skilled machinists, material fluctuations, and then there has been all the Covid related issues. It is 2021 and business seems to be heating up – what extra challenges do you see this year?

JOE: 2021 is going to continue to be a strong and exciting year for EFG.

That said, the challenges you mentioned are probably among the top ones we are all working with. I would also add the state of the global supply chain, logistics, and what is cropping up more and more raw material availability. The days have long passed where I am the youngest person in the room, so I’ve seen a challenge or two over the course of my career. That said, we are living and working in times never seen before.

With the market and business heating up and growing, these challenges lead to the biggest concern of all and that is customer service. Our businesses come in every day ready to serve our customers. While doing that our teams find themselves making difficult decisions ensuring we have our priorities right. With the growing product demand coupled with constrained resources and supply chain we are going to be ‘moving mountains’ as I say for some while understanding we will disappoint others. I wish that wasn’t the case but it is for now. EFG is more focused than ever before on growing and expanding our priorities. I see the progress our facilities and teams are making and look forward to very soon not having to make these difficult choices.

TS: Is Elgin always on the hunt for additional acquisitions?

Joe: As you know, EFG was put together through several acquisitions, even as recent as last year’s acquisition of Rockford Fastener. There are many great companies that would bring strong products and processes that would be complimentary to our company and current product lines we serve the market with. The sponsorship and partnership we have with Audax is very strong and it is wonderful to have the support we do from them. So yes, that is going to continue to be part of our growth strategy.

While we do have a couple acquisition ideas, as I will call them for now, at this point our focus is working our way through the current market and improving our ability to serve it. As I mentioned earlier, I am excited for what our people are doing and the improvements we are seeing. With those continued improvements I wouldn’t be surprised either way to see, or not, an acquisition this year.

Note from TS:

I have a regular column in Fastener Technology International (FTI) magazine, called 10 Minutes with the Traveling Salesman, which can be read online at www.fastenertech.com. Subscriptions to FTI, print and digital editions, are free-of-charge for fastener manufacturers, distributors and users as well as suppliers to the industry.”