Have any of you figured out how COVID-19, or the disease also know as coronavirus is going to affect your business yet? I see supply chain updates and realize some factories have temporarily shut down in other countries. Are domestic manufacturers seeing an increase in fill in orders? Anybody out there from the state of Washington? I think half your state is working from home now. I’m curious to see if ITR Economics offers any updated projections based on this situation. Fastener Fair says the show is still on in Charlotte in May but several others have been postponed. Friends in other industries are cancelling travel plans like crazy and several have told me that their trade shows and larger meetings have been cancelled. Curious if you have any thoughts on the matter.

“You’re just a wave, you’re not the water”

And just like that, January is gone and we are in mid February. I tried to start a post at the end of December but there was too much tariff and impeachment talk and I just couldn’t wrap my head around it and figure out if and how it was affecting the fastener industry. And I don’t know if we can gauge from January how the rest of 2020 will look but several people have told me that their February is looking pretty good so far. We have the Caronavirus causing airlines to cancel flights to China and factories sending out notifications that they are temporarily shutting down. Stuff will not ship, people will change their travel plans (especially if they are stuck on cruise ships) and this will all have a ripple effect. Caronavirus just kind of got tossed into our 2020 forecasts and no one can predict exactly how this will all play out.

Fastener people might have to find domestic sources that can fill in product that will not be shipped from Asia. And the domestic suppliers a anxiously hoping that is the case. And if your customer ships product into that region, you might need to update your forecasts. But once this is settled, there is still a lot to consider going forward.

I just saw an article in Fastener & Fixing Magazine from their January 2020 issue where Jun Xu, president of Brighton Best International shared some thoughts on the fastener and industrial marketplace. It was a great article and you should find it and read it. In the article, Jun shared some thoughts on electric cars when he wrote:

“Electric cars uses 1 /3 of the components of a gas powered car. There is no transmission, no engine block, no axle or exhaust system. There is nothing but a battery and a motor. How will this change our industry when there are 66% less components being used but 3 times more of the 33% of the components being used? From my experience, when there is a higher volume but lower SKU count, it means margin shrinkage and consolidation.”

Caronavirus is a ripple, but what Jun is talking about is a tidal wave. Tariffs are a ripple, but industry consolidation is a tidal wave. And, allow me the liberty of using the lyrics from a Jimmie Dale Gilmore song, where he laments his girlfriend telling him, “babe, you’re just a wave, you’re not the water”. That line just about nails that relationship, doesn’t it?? He knows where he stands.

From the Fastener & Fixing article, clearly BBI is diversifying and striving to stay ahead of the curve, to remain part of the water and not just a wave or ripple. Jun identifies the waves (tariffs, politics) but also the changes in the water itself – technology, markets like the auto industry rapidly converting to battery powered vehicles (just this morning there was a story on the morning news of both the Mustang and Hummer EV’s being introduced). These are huge trends that are completely changing industrial distribution. And clearly, supplier and distributor consolidation are both changes affecting the waves and the water.

There are several fastener industry conferences coming up in the next several months. The Southwestern Fastener Association is having a Distributor Social event later this month. Next month Pac-West and the NFDA will have a table top in California. May brings the Fastener Fair show in Charlotte – but prior to that will be the NCFA Distributor Social on May 7 in beautiful Cleveland, Ohio. Then comes the Mid-West Fastener Show in June and I’m sure I’ve missed several others. These conferences are great and allow us to network and compare notes. See if we are all on the same page. Gives us a chance to sort out the waves from the water.

10 Minutes with Jason Wagner and Ilian Dimitrov of The Richard Manno Co.

This was my first attempt at a two person interview and I couldn’t think of a better team to do it with. Jason Wagner and Ilian Dimitrov are respectively the Executive VP and General Manager of The Richard Manno Co. While The Richard Manno Co. has been around for many years, Jason and Ilian are the current management team and have been instrumental in taking the company “to the next level”.

The company was founded by Richard Manno in 1978 and sold to current owner, Vincent J. Manno in 2004. Richard eventually retired in 2009 and the company has continued to grow under the management team of Jason and Ilian. Through continuous improvements in their processes and investments in new facilities, equipment & personnel, the company continues to make every effort to “exceed customer expectations”. The Richard Manno Company is an ISO 9001:2015 and AS 9100 Rev D certified manufacturer. They are ITAR Registered as well as a QSLM/QSLD Class 2 government approved supplier.

TS: You two are “guiding the ship” at Richard Manno & Company. How long have you two been working together and how did you end up at the company?

Jason: Ilian and I have both been with the company for over 9 years. I came from a finance background and Ilian was in print media.

TS: Ilian, you are from Bulgaria. How did you end up in the U.S. and then specifically in NY at Manno?

Ilian: I was second year in college in Bulgaria, when a friend of mine asked me to go with him to an interview for students who wanted to study abroad. The interview was organized by Ohio State University. I decided to give it a shot and actually got picked right away. A month later I was in the USA starting a new chapter of my life. I completed my internship in Ohio and moved to New Jersey where I graduated from Montclair State University with a major in Business. A few years later I got an opportunity to join the Richard Manno Company. I didn’t hesitate because I always enjoyed manufacturing. I went to high school which specialized in CNC programing and also worked for my uncle’s machine shop. RMC was a perfect fit for me and I finally realize why they say people who work in this industry always stay in it.

TS: So, in the last few years you guys have been responsible for re-inventing the Richard Manno Co. You’ve essentially recreated the company. Tell me about some of the changes that have taken place over the last several years.

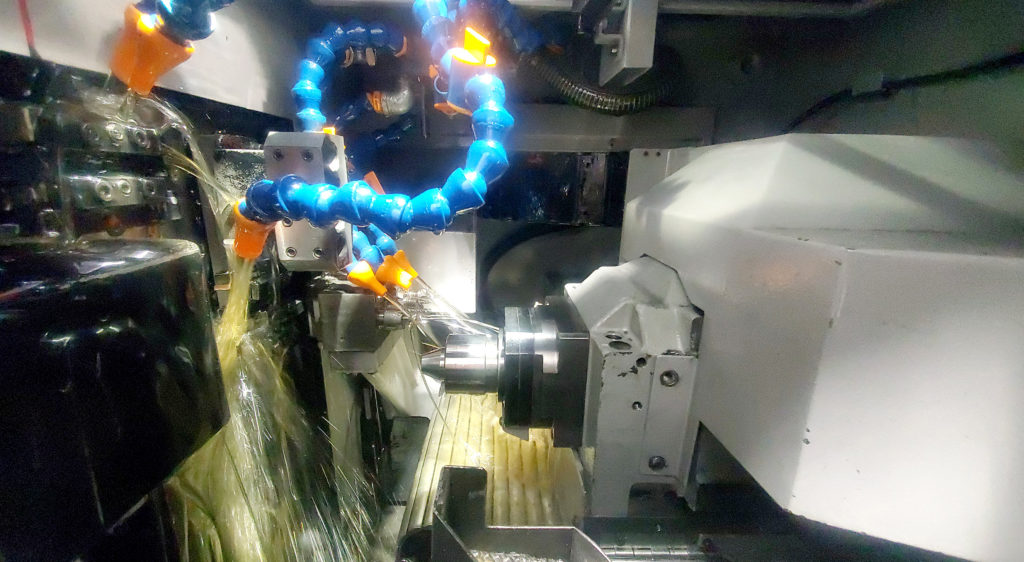

Jason: While Richard Manno Co remains a stocking manufacturer for large catalog houses, up until mid-2014 we were just a job shop for spot buys and small runs on per print items. At that point we had nearly 150 machines but did not have any CNC Swiss Lathes. We knew that in order to be competitive on long running high volume jobs as well as intricate Aerospace, Medical and Military parts we needed to move into CNC Swiss machining. In 2014 we purchased our first 2 of these machines. In 2016 we purchased another building and expanded our CNC Swiss, CNC Lathe and Escomatic departments. By the end of 2019 we maxed out the capacity of that building and started replacing some of the older equipment at our original location with CNC Swiss machines in order to continue our growth in that area. During this process we have maintained our QSLM Class 2 approval, ITAR Registration and transitioned from ISO9001:2008 to AS9100 REV D in 2018.

TS: In the past people might have thought “electronic hardware” when they thought of the Richard Manno Co. What new market segments are you targeting? Where are you seeing your biggest growth? What kinds of parts are you making today that maybe you did not make in the past?

Ilian: The areas that we are targeting are Aerospace, Military and Medical with our biggest growth being in Aerospace. Some of the parts that we have made in the past would have required numerous secondary operations, most of which had to be completed one piece at a time. With our investment in equipment and personnel, we can drop those parts complete or near complete which makes us competitive on higher volume runs. We can be the source for prototypes, mid-size runs and long runs from commercial parts to tight tolerance precision components. Not only did we expand our capacity in terms of production volume we are now able to produce parts with features that we were not capable of producing in the past.

TS: You still stock product for stock and release programs. What kinds of parts do you have in stock for someone looking to just buy product from your inventory?

llian: We stock shoulder screw, dowel pins, thumb screws, thumb nuts, captive panel screws, spacers and standoffs in a variety of materials and finishes some of which are certified to Military and Aerospace Standards.

TS: The commitment to become AS 9100 certified is substantial. There is a large investment of time and resources to achieve that certification. Why did you go after it? Did you have business you knew you could go after with AS 9100 certification? Did your customer base request it of you?

Jason: This decision was customer driven as we had numerous requests from various customers to become certified. By becoming certified it has opened up additional opportunities with existing customers as well as with new customers. Simply put, there were parts that we couldn’t produce without it.

TS: The Richard Manno Co. has been in business for many years. What business trends do you see affecting Manno and affecting the fastener industry in general?

Ilian & Jason: Automation, overseas pressure, and cost and availability of skilled labor.

TS: Look into your crystal ball and tell me what you see for the Richard Manno Co. in the next several years?

Jason: Growth through re-investment in the company and continuous improvement.

TS: What is one thing about the Manno Co. do you think would surprise people who think they know the Manno Co.?

Ilian: We stock over 6,000 different SKU’s. Not too many manufacturers stock as much as we do. While we are not a huge company, a lot of people do not realize how much benefit there is to doing business with us.

Note from TS:

I have a regular column in Fastener Technology International (FTI) magazine, called 10 Minutes with the Travelling Salesman, which can be read online at www.fastenertech.com. Subscriptions to FTI, print and digital editions, are free-of-charge for fastener manufacturers, distributors and users as well as suppliers to the industry.”

10 Minutes with Tim O’Keeffe

TS: Every time I turn around I run into the name Tim O’Keeffe. Paging through the most recent LINK magazine I saw an article on the “Fastener Advisory Board” that was written by you, then just a few pages later I read where G.L. Huyett is now a Sherex Master Distributor. First, tell me about the Fastener Advisory Board.

Tim O’Keeffe: FAB Group was started by the NFDA some thirty years ago as a non-competing peer review group, distributor-focused, along the line of Vistage and Young Presidents-type organizations. Our group is the only remaining one, and counts Ron Stanley of Empire Bolt; and Screw and Don Nowak, retired from Falcon Fastening Systems, as founders and alumni. I have gotten a lot out of it. We are trying to recruit another distributor member and we write those articles to keep our name out there, in the event there are other like-minded professionals. I think I could say FAB has been life-changing for me, both personally and professionally. On another level, it can be lonely as a CEO in the fastener business, what with our varied locations, and thus I count some of my best friends among the FAB members.

TS: How did the Sherex Master Distributor situation develop?

Tim O’Keeffe: I know Adam Pratt through FAB Group, so I suppose one could say the idea was hatched from that introduction. We try and maintain very careful boundaries in FAB with respect to conflicts of interest and such. I would like to think Adam would have considered us anyway, as we try and support the OEM distribution supply chain as a supplier partner with firms like Sherex, and a focus on distributor support. The Sherex arrangement was made more complicated by the fact that we are an AVK master distributor as well. We commenced the AVK relationship in 2015 when we bought Precision Specialties. Since that time we have more than doubled our AVK share, and we like that line and work hard for them. Our intentions are mutually exclusive but related when it comes to our arrangements with Sherex and AVK. We think we can grow the Sherex business and the AVK business concurrently because we fill a gap in the supply chain for OEM fastener distributors, and we bring a lot of value-added services in engineering support and operational excellence, such as offering product certifications free of charge on a “no-touch” basis on-line. We want to help increase the market size of what we refer to as the industrial skincraft market. There remains a lot of new design-in options out there.

TS: Aztec Lifting is your most recent acquisition. And before that I believe it was Tinnerman Distributor, Precision Specialties. So you have been growing through many different channels – some acquisitions, some product extensions, and then acting as a master distributor. Can you give us any insight on your growth strategy?

Tim O’Keeffe: Our growth strategy is distributor focused grounded in product expansion and operational excellence. We opened a Technology Center in Sidney, Nebraska about a year ago, so as to leverage the talent pool from the former Cabela’s organization, which has been consolidated with Bass Pro Shops. We are scaling that operation to rapidly increase our pace in new product expansion; product content creation with an eye on communicating features and benefits more simply using media videos and storytelling; and additional technology tools. For example, we are releasing new on-line tools so our customers can quote custom lifting hardware such as clevises, yokes, turnbuckle assemblies, and special eyebolt configurations, instantaneously, self-directed, and with just a five day lead time. We demonstrated the tool at the STAFDA show in November and found it challenging to communicate how easy and instant the tool is. It is so good as to be non-believable, and is something we hope to expand to other custom parts categories. In addition we continue to invest in technology and talent in enriching the customer service experience. Internally we maintain dashboards that measure response time to RFQ’s. We know that speed kills. We have specific training plans that are elevating the product knowledge of both our inside and outside sales teams. Our outside sales team now covers all of North America so we can work shirt-sleeve-to-shirt-sleeve with distributors to solve problems and add revenue to their own sales mix.

TS: If I’m not mistaken, you purchased G.L. Huyett, correct?

Tim O’Keeffe: Yes, in November, 1992.

TS: What did you do before you bought out Huyett and what was some of the company history before you acquired it?

Tim O’Keeffe: I am a liberal arts major with a minor in philosophy and so while I always knew I wanted to be in business, my education was limited in the field. In 1985 I started a business brokerage in Kansas City and was one of the founding members of the International Business Broker’s Association. I knew I could learn a lot about business in that field, and I did. From 1985 to 1992 I closed on 300 deals– everything from a corner dry cleaner to manufacturing companies. I liked the business, but it had no residual. You sell a deal and you are out of business and have to find another client. I knew I wanted to buy a business. In 1992 I met Bob Hahn, the true creator of G.L. Huyett, in a tin shed in the middle of Kansas. I liked him, respected him, and knew I could learn a lot. There was a nostalgic appeal to me about the industry. I like the fact that the fastener business is part of the Great American Industrial Machine. We build stuff. We create tangible products. We work in and employ blue collar people. G.L. Huyett was nearly 100 years old at the time, though small and sleepy. When I bought it, the company had one employee along with Bob and his wife Dolly. The business originated in 1899 when Guy Huyett, a German immigrant, bought the hardware stock of the Globe Department Store in downtown Minneapolis, Kansas. The business continued as a single product line machinery bushings business for the first 80 years or so, selling into two step hardware distribution such as Stowe Hardware in Kansas City and Orgill Brothers in Memphis. These distributors would in turn sell into retailers, hardware stores, and farm implement dealers. Machinery bushings were considered a precision part in the day, taking up the slack on shafts. It was known that during the summer, townsfolks in Minneapolis would gather under a shade tree on Sunday afternoons, next to the tin shed plant we had, and wire machinery bushings into rings of 10, 25, and 50 for packaging. They would sip whiskey and called themselves the Sunday Southside Sipping Society, or “SSSS”. Bob started selling new customers and adding product part time starting in about 1978, while he was a professor at St. Cloud State University in Minnesota. Ironically he counted Will Oberton of Fastenal as one of his students and they remained friends for many years. As with me, I think Will thought of Bob as a mentoring figure and teacher in his life. That’s the person that Bob was.

TS: I notice you guys put a lot of effort into you booths at the IFE Vegas Show. I always enjoy the creativity and effort. Tell me about your approach to that trade show.

Tim O’Keeffe: The IFE show has changed, and our strategy has changed as well. When we first started, costs for the show and for traveling to Las Vegas were a lot less than they are now. We were the first booth to serve beer and our first booth was an actual Wild West Saloon. I even went out into the desert and got real tumbleweeds to stack on the roof. Now it is getting so expensive that we are gradually lowering our standards, so as to lower costs. My sense is that this mindset is shared by a lot of other exhibitors as well. I am on an advisory board for the show managers and I have pleaded for a reduction of the show to one longer day, say 9:00 am to 5:00 pm. They show no interest because they make too much money on the second day, even though hardly anyone goes. If they don’t listen, I predict a slow and gradual reduction in attendees and booth spaces, and perhaps other shows such as Fastener Fair might increase in relevance. There are too many shows as it is.

TS: I know you have a lot of interests outside the fastener industry and I know your company is very involved in your community. What are some of the community activities you and your company are involved in?

Tim O’Keeffe: Community development and charity are sacred to G.L. Huyett. We support six scholarships in our local high schools for college and trade schools each year. Each July we buy tokens for free rides for disadvantaged youth to the County Fair. Our fair concession is actually owned by a local non-profit because our fair is too small to attract carnival concessionaires. Our signature charity is Project Drive, an annual grant program of $50,000 for local non-profits. We have built handicap ramps for high school football stadiums; donated computers to schools, and have donated so much equipment to food pantries and old folks’ homes that I cannot even count. Ironically one of our grants was to buy a Scrambler carnival ride for the County Fair a few years back. Revenue from ticket sales has provided capital to buy more rides, including a Ferris Wheel. Last year we built a Community Garden and our employees grow and raise crops for food pantries. They also serve food at an annual Salvation Army Thanksgiving Day Dinner each year for homeless and disadvantaged persons, and G.L. Huyett donates all of the turkeys for that event.

TS: Where do you see our industry headed? If you were to look out 5 – 10 years, what changes do you see coming?

Tim O’Keeffe: Well, Marty, you know me. I will answer with honesty and my views of the future probably differ from others. For starters, the concept of product is going to change. The drive trains for battery-powered vehicles are much simpler and have a hell of a lot fewer fasteners than internal combustion motors and their transmissions. I could not believe the market for battery-powered tools at STAFDA. I saw a battery-powered generator that will run electrical power tools for eight hours. You can put that unit into a duck blind and feed your friends three meals and watch two football games without a trace, short of the smells of bacon and steaks cooking on an electric griddle, and ducks would not hear a thing. Distributors at the show told me that 80-90% of their power tool sales are battery versus gasoline. That same change will come to cars and transportation. The market for fasteners will decrease, further fortified by the continued development of composites and adhesives to make things lighter in weight. Fastener engineers might move from exclusively studying bolted joints to smelling glue all day—maybe that is not such a bad thing! One has to think the supply chain will change too. Technology will most likely wire the factory line more closely to the fastener production line. Inventory and time are costs and to drive down costs, the supply chain needs to shrink. I know I hear that most people still think personal relationships are important, and e-commerce is nothing more than an ordering portal– I disagree. Robots, machines, AI, and e-commerce are the future, and if you wait too long to organize your data and wire your ERP to the web, it may be too late.

10 Minutes with Allan Weitzman

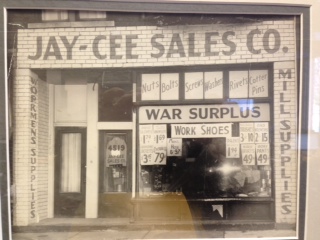

TS: OK, first thing first…where did the name Jay-Cee come from?

AW: The name Jay-Cee Sales came from my great grandfather Jack Clinton.

TS: Tell us more about the company history.

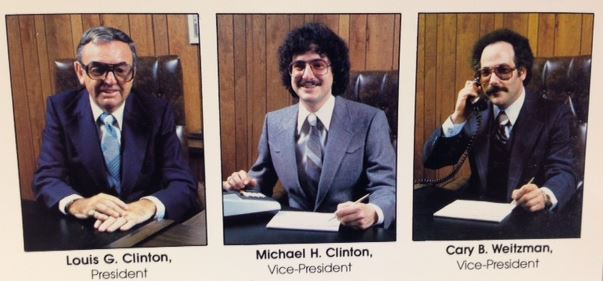

AW: Jay-Cee Sales was

started in 1948 by Jack Clinton in Detroit, Michigan on Grand River. The store

began as an Army/Navy supply store as well as other basic goods. Soon after the

business opened, Jack was joined by his son Louis Clinton.

Jack had a brother-in-law who was in the

scrap/surplus business in Texas. He came across a surplus of various goods and

fasteners, which included rivets and shipped them up to Jack. As soon as he

received the shipment, he was able to sell them in no time. As business increased, Jack and Louis needed

to move to a larger location with a warehouse to store their increasing

inventory. In the mid 1950’s the company moved to Ferry Park in Detroit.

In the coming years business continued to grow.

In 1969 Louis’s son-in-law, Cary Weitzman joined the company. Shortly

thereafter, Louis’s son Michael Clinton joined the company in 1972. In 1973

Jay-Cee Sales decided to divest all of their threaded products and concentrate

on rivets. Again, Jay-Cee Sales out grew

its building and relocated to Farmington, Michigan in July 1, 1974.

Sadly, Jack Clinton passed away in 1980 at the

age of 83. On October 20, 1980, Jay-Cee Sales was incorporated and became

Jay-Cee Sales & Rivet Inc. Business thrived. The company added an

addition to the warehouse in 1984 to a total of 40,000 sq. ft.

Unexpectedly, Jay-Cee Sales & Rivet was dealt a huge

blow when Louis Clinton passed away in 1993 at the age of 66.

In the years that followed, Jay-Cee Sales &

Rivet was joined by its 4thgeneration when Greg Weitzman (1994),

Allan Weitzman (1998), Jason Clinton (2003), and Bryan Clinton (2003) entered

into the family business.

TS: Most fastener people know you guys as the rivet experts. You carry just about every style of rivet. How did your company come to focus on that niche?

AW: When Jay-Cee began selling fasteners, they realized the rivet market at the time, was a lot less competitive and they knew the rivet line inside and out. Even today other fastener houses express frustration as to their lack of knowledge when it comes to rivets. Between the 8 salesmen, we have a combined 185 years of rivet sales. We pride ourselves in being the source of knowledge when it comes to rivets.

TS: And then, after getting out of the bolts and nuts business, you and your brother circle back around and get right back into the nuts, bolts, screws and other fasteners.

AW: Yeah, that’s true. In 2015 Greg

and I established a separate company, Value Fastener, LLC. Value Fastener was

designed to be an online based company, selling fasteners that did not compete

with Jay-Cee Sales like screws, nuts, and bolts. The company prospered over the

next few years, highlighting the Value Fastener brand throughout various

industries. Expansion was on the horizon and the we determined that it might be

best to be acquired by Jay-Cee Sales, which, in 2019 purchased Value Fastener

as a Jay-Cee Sales product line.

Value Fastener adds over 32,000 parts, with 4

shipping locations throughout the US and specializes in bulk

packaging. Together the merger created a true fastener house that

boasts one of the largest inventories of rivets and now a complete line of

threaded fasteners all under one roof. Rivets can be ordered online at www.rivetsonline.com and Value Fastener host their own e-commerce store

at www.valuefastener.com

TS: From our discussions I can tell your company is very customer service focused. It is important to you that you treat small customers just the same as you would handle large customers. Share with me your philosophy on customer service.

AW: Fasteners are such a commodity purchase. It’s typically one of the least expensive purchases in a production buy. We understand that and realize the purchaser, on the other end wants to get their fasteners purchased and move on to their more complex purchases. Our goal is to reply to rfqs, emails/faxes within an hour or less for standard parts. With 8 salesmen on staff, this is easily completed. Phone calls are also answered right away. The sales team members at Jay-Cee Sales are all very personable and were put into their positions for their people skills. We have a lot of customer service people for the size of our company but it’s important that the level of service we offer stands out. That $25 customer is just as valued as the $250,000 customer. They both deserve our time, attention, and customer service.

TS: You have an impressive online presence. And I know you have worked hard on your e-commerce business. Have you had a lot of success with e-commerce?

AW: We had an outside company produce our ecommerce sites (www.rivetsonline.com) and (www.ValueFastener.com) but we had a very influential hand in building it and we maintain 95% of it. We understand the way our customers shop, so having a hand in the process, it was designed by fastener people who understand how fastener customers shop. Not just by some website developer who doesn’t understand the industry. It has been successful, but nothing can compete with 2 people communicating over the phone or in person. It’s the only way to develop and maintain relationships.

TS: Jay-Cee has a lot of family involved in the business. That can be a wonderful thing and it can also present challenges. How has it gone for your company?

AW: Currently the business is run by me, Greg Weitzman, Jason Clinton and Bryan Clinton. The four of us get along well and we all have our individual roles. We’re 4th generation and the business means a lot to us. It’s not just a place of employment. It’s a legacy and we’re very excited and hopeful that we’ll have a 5th generation family member in here one day. The company has 17 employees. We all know each other’s husbands, wives and children. Everyone is family!

The biggest challenge for me and Greg was losing our father, Cary Weitzman, this past March. When someone special to you passes away, work is helpful to get your mind off of things and give yourself a mental break. But for us coming to work did the exact opposite. Every day is a reminder he’s not with us anymore. His office is still here. His desk is just the way he left it. His name is still on the payroll form. As time goes on those things trigger nice memories and funny stories. The phone calls, letters and emails about my dad still continue today. Its great hearing from customers and vendors about my dad and reinforces how lucky we are to have a family business with such great people to conduct business with.

TS: I met your dad several times and I too was a “son of” so I feel truly sorry for you and Greg. And as we both know, the best thing we can do for ourselves and in honor of those whose large shoes we try to fill is to keep on keeping on and carry on the legacy. With that in mind what do the next few years look like for Jay-Cee Sales?

AW: We’ve had strong growth over the last few years and we expect that to continue. With the new product lines we have added with Value Fasteners we’re putting some heavy focus on these lines. It has been a good venture thus far. We’re planning on hiring an outside salesperson after the first of the year. We’ve always been an “inside” sales company and this new approach is exciting and we’re eager to see what new opportunities open for us.

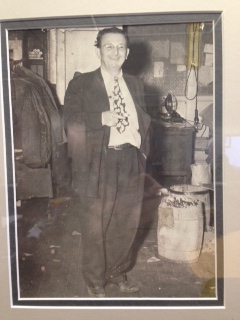

JayCee founder, Jack Clinton

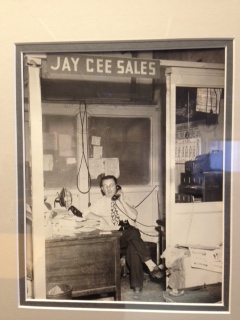

Jack Clinton selling some rivets

JayCee started out selling army surplus, pants, socks, work shoes & fasteners

2690 Ferry Park St., Detroit, MI Location till 1974, pic taken in 2012

Taken in the 1970’s

JayCee Current Headquarters

The Gang

Interesting Observations on Electric Cars

I recently stumbled on an article that I am re-posting below. I was casually reading this article, found it interesting, and then right near the end, the author mentioned Rock Valley College which is the college that offers classes on cold heading. Representatives from Rock Valley College participated in the Fastener Coalition’s Fastener Summit a couple years ago. The author of this article, Ernie Redfern, lives in Rockford, Illinois which a city with a rich fastener history. I wrote to Ernie asking if I could reprint the article and his response was also very interesting:

“No problem at all. I think it is EXTREMELY important that we reinforce the issue with all-electric. I believe the Big 3 in Detroit, not really known for the far thinking, are teetering on becoming extinct. I do not say that without sadness. This country was a big leader in the internal combustible engine (ICE) world. Our problem is we still think we are the leader in the world of automobile markets. China is the clear leader, surpassing us two years ago, and if you review the projections, in a decade will be double the size of the U.S. market. India is also screaming forward – we may find ourselves third on the list.

Although combating climate change is a big factor in the push for all-electric vehicles, dependence on foreign oil is another. The rise in the number of car owners in China and India, the two most populated countries, means those countries must spend more foreign currencies on oil imports while the increased petrol vehicles contribute to an already dismal pollution problem. Electricity is viewed as an energy source that can be domestically produced while combating climate.

Tesla has projected that in 2 years their battery will go from a 400,000 mile life today to a 1,000,000 mile life. Go to the GM web site on the Bolt EV https://www.chevrolet.com/electric/bolt-ev-electric-car – the only maintenance needed is rotating tires every 7,500 miles, replacing cabin air filter every 22,500 miles and periodically checking the brakes. Somehow Tesla can get 370 miles while GM ekes out 238 on a full charge. “

And, with that introduction, here is the article from Ernie Redfern:

As the longest United Auto Workers’ strike in 50 years against General Motors winds down, the underlying tensions will remain. Over the next few years, GM plans 20 new electric models, mostly in China, funded in part by U.S. plant closures and other cost-saving measures so that GM can get the $6 billion it needs per year to bring these cars to market.

From the outside, it may seem a cruel irony that U.S. workers will bear a disproportionate penalty for GM’s ambitions in China. But it’s really about the fight for survival of the U.S. automobile industry. In the next generation of automotive transportation – the all-electric vehicle – the U.S. must remain relevant.

Americans’ love affair with the internal combustion engine might be the undoing of our domestic automobile manufacturers. I told a piston-head friend that gas-powered vehicles are taking the elephant walk into the graveyard. His reaction was fast and furious: “I will NEVER get in, or drive, an electric vehicle!”

Volkswagen Group, the world’s largest auto manufacturer, projects that by 2040, all-electric cars will make up 70 percent of new cars sold in Europe and 60 percent of new cars sold in the United States.

In March 2019, all-electric cars made up 60 percent of new sales in Norway, which is banning gas automobiles by 2025. Denmark, Iceland, Ireland, Israel, Netherlands and Sweden have targeted 2030 for the end of new sales of petrol vehicles (which include those with diesel engines). By 2040, that ban would extend to France and the United Kingdom.

China, by far the largest auto market in the world, wants 85 percent of its vehicles to be all-electric by 2040. To reach this target, that government is restricting the number of new petrol vehicles that can be registered.

Germany, about the size of Montana, has committed to installing 1 million charging stations by 2030 with 100,000 being installed in 2020. The U.S. Department of Energy estimates 68,800 stations in this country today.

The State of Illinois’s status? Starting in January 1, 2020, owners of all-electric vehicles must pay an annual fee of $100 in addition to standard registration fees. The Illinois Citizens Utility Board projects that in 10 years we could have as many as 2.2 million all-electric vehicles (30% of all passenger vehicles) registered if we get serious about climate change.

If the U.S. and Illinois are behind, Rockford is in the stone age. There are only 14 public charging stations within a 10-mile radius of downtown Rockford – not one of them on the west side of the Rock River. The City of Rockford, unlike the State of Illinois, has no target on converting part of their fleet of vehicles to either all-electric or hybrid. A check with city officials shows that Rockford has no plan on how to generate revenue from the emergence of all-electric vehicles. And no guidelines are in place for infrastructure investments related to electric vehicles. An example is putting in new city sidewalks without conduit that would allow the city to easily install charging stations later.

As we go all-electric, it is estimated that, worldwide, we eventually will lose 3,000,000 automobile industry jobs. The all-electric vehicle requires 30 percent fewer parts. A UAW study projects they will lose 35,000 jobs in the next few years in the shift to all-electric.

If in 20 years we go to 60 percent all-electric vehicles in the United States, we have concerns to address now:

- Will our aging electric distribution system be able to meet this new power drain?

- A lot of corner gas stations/oil-change centers are going to close. What type of environmental cleanup will be needed and what repurposing is possible?

- With limited gas tax support, how will road improvements be funded in the long run?

- Where are the best places for public charging stations?

- Can we make Rock Valley College a national leader in this technology?

A ship has sailed with the rest of the world on it, and here we are standing on the docks with our gas can in hand. Let’s wake up and protect our place in the automotive world. Even Harley Davidson is going electric.

Ernie Redfern is a Rockford resident.

10 Minutes with Larry Kelly

TS: A lot of people might not know this but I have a long background with Buckeye Fasteners, Ohio Nut & Bolt and Modern Fasteners. Actually, not so much Buckeye but the other two companies. Before my father became a manufacturers rep he was a sales manager for Modern Fasteners for over 20 years. When was Buckeye actually created?

LK: Buckeye was set up in 1972.

TS: OK, and I believe my dad left in 1976 so there was overlap. Briefly, share with us the history of Ohio Nut & Bolt and Buckeye.

LK Our company was founded in 1905 as the Ohio Nut and Bolt Company. The first products manufactured were bicycle chains back when bicycles were a main mode of transportation. In 1928, Ohio’s first large, commercial use of weld screws were on the Model A Ford. The first HW weld screw was used on the frame of the Model A to allow one handed assembly of the fenders. In 1972 Buckeye Fasteners was set up to sell and distribute products to our ever expanding customer base.

TS: Well, somewhere in the 1960’s and early ‘70’s when my dad had to go into the office on Saturdays, me and my brother would run around the warehouse and roll boxes down the conveyor belts to amuse ourselves till my dad was done. And, we raided the coffee area and ate sugar cubes from out of the cabinets!

LK: We have always been aware of missing inventory and some accounting discrepancies and I think you just solved that for us.

TS: Yeah, we raided that sugar cube inventory, that’s for sure. But moving on from that… your company is an employee owned company (ESOP). When did that happen and how did that come about?

LK: Late in the year 1979, the family owners decided to sell Fastener Industries, Inc. Richard Biernacki, then Treasurer of Fastener Industries, knew of Employee Stock Ownership Plans (ESOP’s) and suggested that the employees buy the Company. The employees could do this by individually transferring monies from their profit-sharing accounts to an ESOP and with a loan from National City Bank could meet the total asking price. The all-cash offer was accepted. The employees individually invested 85% of the total profit sharing monies to buy the company. The transaction closed on June 30, 1980 making Fastener Industries, Inc. a 100% ESOP-owned Company with all employees owning common stock as of the year-end.

TS: What are some of the benefits and challenges of being an employee owned company?

LK: The culture in an Employee Owned Company is very unique since each employee has a stake in the company. Every Employee Owner is aware that their job performance has a direct impact on the company and ultimately a direct impact on them as owners. All of our Employees know how the company is doing on a daily basis since financial information is shared with everyone. One of the biggest challenges is trying to avoid the sense of entitlement since everyone is an owner. We consistently need to remind ourselves that the ESOP is the type of company we are, however, we do not run our business and make decisions based solely on this fact.

TS: How long have you been with Buckeye?

LK: I’ve been with Fasteners Industries, Inc. for 35 years. 27 years with Buckeye Fasteners and 8 years at Ohio Nut & Bolt.

TS: To me you are one of the “faces” of Buckeye Fasteners. You are at the trade shows, you are out in the field making sales visits. But what was your pathway to get to that point? What jobs have you held along the way?

LK: I started my career with Buckeye in 1984 in the warehouse picking parts and shipping orders. A year later I transferred to Ohio Nut and Bolt and took a job in the maintenance department where my responsibilities included repairing manufacturing equipment, making tooling and maintaining the building. In 1989 I took a position in the Nutformer department were I set up and ran two headers and four tapping machine. It was here were I really learned about cold heading and the manufacturing of fasteners primarily weld nuts. This was the only department at the time which did both the primary (cold heading) and secondary(tapping) operations to make a finished part. In 1993 I moved back to Buckeye taking a job as an inside sales representative dealing with customers on a daily basis. Throughout all these career changes with the company, I was attending Cleveland State University in the evening working my way towards a college degree. I graduated in 1999 with a Business Administration degree and was appointed Sales Manager for Buckeye Fasteners. I worked as the Sales Manager for 15 years and I’m currently the Business Development Manager. I’m also serving my second term on our company’s five-member Board of Directors.

TS: In my earlier years in the industry I don’t recall Buckeye being involved in the fastener associations or trade shows quite like I have seen them in more recent years. I think you have had a big influence getting Buckeye more involved in these groups.

LK: Our company always had a history of being involved with the ESOP Association and various manufacturing related groups like AWS, SME and RWMA. We didn’t have a presence with any of the Fastener Associations to speak of so when a was appointed Sales Manager I started looking into some of the associations. The company decided to become a member of the NCFA which was the start for us getting more involved in the fastener associations.

TS: And you did get involved! In fact you were the NCFA resident for three years.

LK: I’ve always believed if you are going to get involved with something you need to really get involved. When we joined the NCFA I looked into becoming part of the board and was appointed as a Trustee. I served as Trustee for a few years and was fortunate enough to be elected Vice President for a two year term. After serving as Vice President, I was again blessed to be elected President a position I held for three years. Being President of NCFA was a tremendous honor since I got to meet some of the most influential people in the fastener community. Bob Baer, Rich Cavetto, Rick Rudolph, John Radel and Hall a Famer Marty Nolan just to name a few. My experience with the NCFA also lead us to join other associations, MWFA, NEFDA and NFDA all of which provide a tremendous amount of networking opportunities for our company.

TS: What are some of the current challenges for fastener manufacturers in today’s fastener industry?

Making a quality part at a fair price and providing the best customer service possible is a challenge for any fastener manufacturer. Quality is becoming more and more challenging since customers are demanding zero defects especially when dealing with the automotive industry. Being a domestic manufacturer since 1905, we are constantly feeling the pressure from non-domestic sources competing for our business. The recent round of tariffs also created challenges for us since many of the materials we purchase to manufacture are products that were impacted by these tariffs. Technology is an area any fastener manufacturer needs to keep themselves educated and up to date on. There have been so many advances in our industry such as 3D printing and the newer types of materials being used by our customers to manufacture the products they produce. We are constantly attending conferences and seminars to insure we have the tools and resources to stay competitive.

TS: What does the future look like for Buckeye Fasteners?

Buckeye Fasteners is constantly expanding our product offerings to meet our customer’s demands. This includes parts we manufacture as well as products we distribute. We are also on lookout for potential acquisitions to help increase our presence in the market. As mentioned earlier, technology is a big part of our focus and we recently launched our own Buckeye Fasteners App available in App Stores (Thanks George Schrull). The App basically does everything our website does and more. With more and more business being conducted on mobile devices we thought it would be important to adapt to this technology. We’ve also put a lot of effort into our website to reach a more tech savvy audience.

Four legs and wings would basically sum up what keeps my beautiful bride of 32 years Jackie and me busy. We have two Golden Retrievers, Finnegan and Theo who keep us quite active. You can typically find us walking them first thing in the morning before we head off to work and again in the evening. We walk them around 3 miles per day regardless of the weather. The only time we won’t walk them is if it’s below Zero. We have also been enjoying the wonderful world of Beekeeping and we are in our fourth year. Jackie was always interested in Honeybees (mostly out of her love for Winnie the Pooh) so we decided to take some classes and learn more about it. The classes educated and encouraged us to start an Apiary. We wanted to help the Ecosystem since the Honeybee is so important to our existence. Honeybees are responsible for pollinating 70% of the fruits and vegetables we put on table and the honey we extract is the sweet reward we get from keeping bees. Family and Friends have come to expect receiving some of our honey for special occasion like Birthdays and Christmas. As I mentioned earlier, I really like getting involved and so I’m currently the Vice President on the Great Cleveland Beekeepers Association which also keeps me busy.

Vegas, HOF and looking forward

About a week has gone by since the International Fastener Expo and I feel like I’ve needed about a week to decompress. For those of you that have not heard, I received a great honor in Vegas and was inducted into the Fastener Hall of Fame. Yep the very same one I’ve written about in the past when I took a memorable road trip with Eric Dudas and Jackie “kind of a big deal” Ventura to recover the HOF pavers before they were turned into rubble. I find it a little humbling to talk about but a very nice honor all the same. I was asked to give a short speech and my only regret is that there were so many people to thank with so little time – I just bailed, literally said “screw it” and dropped my notes cause I felt I was talking too long. I did thank some, missed others but want to thank everyone who has interacted with me over the years in this fine industry and has networked with me enough that somehow my name came up for consideration.

I want to thank the IFE and Emerald Expositions for being great hosts and for the many kind gestures they made to me as an HOF honoree. Their generosity was significant and unexpected. And I still have some whisky left – part of their generosity! Thanks to the Fastener Industry Coalition (FIC) for electing me (and Ed McIlhon) into the hall this year. The FIC is a dynamic and (in my opinion) underappreciated industry group. Think about it, the FIC is made up of representatives from EVERY regional association, the IFI, WIFI, NFDA, YFP and the Fastener Training Institute. I hope the FIC will rise up to be an even bigger player in our industry and I really hope the regional associations with think long and hard about who they are sending to be the representatives for their groups. If someone ever can harness the full force of all these groups working together towards a common goal – that’s a lot of fire power!

Finally, thanks to Bob Baer of Abbot Interfast for introducing me at the ceremony. I encouraged Bob not to over think (or over rehearse) the intro and what came out was a genuine, sincere intro from a good friend. Thanks. I mentioned the ladies from Fastener New Desk, I mentioned Brian and Eric, I mentioned the people who over the years have allowed me to represent them, I mentioned the fastener associations I have worked with including Lisa Graham, Nancy Rich & Vickie Lester. However there were a couple groups of people I forgot thank –

To the many customers I have called on for 34 years who have welcomed me into their facilities and allowed me to be part of their supply chain, I cannot ever express how thankful I am. I promise you, I always value your time and hope I never come into your places of business without something of value cause it has always been important to me not to waste your time. And even better, after 34 years I consider many of you good friends. Thanks Allan Weitzman for your friendship and continued support!

To those long standing principals who have stuck by me over the years, I cannot thank you enough. I have a contract between my rep agency and Chicago Hardware that is older than I am (58) and while there are never any guarantees I look forward to continuing that relationship into the future. Thank you to the Herbstritt family and their fine team. Thank you to team Solution Industries for enabling me to spread my wings and pursue opportunities anywhere in the country. In the early days with John Radel I asked about a territory and John replied, “you can go anywhere in the world and give yourself any title you like”. That sentiment has never changed and I enjoy the support and encouragement to be creative and break barriers trying to bring their story to new markets.

Thank you to Tim O’Keefe and the great people at G.L. Huyett for an unexpected but very much appreciated congratulations gift. Did not expect it but your kindness shows what you’re all about.

I’m still skipping many people but again I don’t want to make this into a novel. And, I said in my acceptance speech, there is still a lot of work to be done. In my speech I mentioned that there have been, and continue to be a lot of mergers and acquisitions but in the past it was largely one distributor buying another or one supplier buying another. Today we see a lot of M&A activity but it is frequently acquisitions being completed by holding companies or investment firms. On October 8, STAFDA is hosting a webinar called “The Coming Commoditization of Distribution: Disruption & What You Can Do About It”. In the webinar description they mention specifically the “external players” entering the industrial marketplace including Amazon, Berkshire Hathaway, Google and Walmart. And just about a week or two ago the ladies of Fastener News Desk posted a link to a McKinsy & Company study called “The coming shakeout in industrial distribution”. Pretty much the same topic as the STAFDA webinar.

I cannot say enough how much I appreciate being a proud member of the Fastener Hall of Fame. But I hope and feel that there are many good days ahead and there are still many career goals I have to accomplish. So, thank you for the honor and let’s get moving on the next chapter because I think we all can see we are heading into some uncertain times in the next couple years.

IFE – The Vegas Show

If you are going to the Fastener Show next week there will be a welcome reception at the Daylight Pool at Mandalay Bay on Tuesday evening starting at 6:00 pm. I’m going to be hanging out at a cabana right in a line next to cabanas reserved for Solution Industries, “The Associations”, Baron Yarborough (The Bearded Nut) and WIFI. Stop in, say hello and if we haven’t met before I hope you’ll introduce yourself. IT’S VEGAS TIME!!

Some things never change!

And this is how it all started….

http://fastenerblog.blogspot.com/2006/10/fastener-industry-future.html