Last year, I had some information to share about recent developments at a company I represent. I sent that information out through the USPS, and in the following weeks I visited customers in person and discussed the same material face-to-face.

The responses were interesting—and sometimes funny.

Almost all of the “old timers” I visited (meaning people within about ±20 years of my age) had received the information, looked it over, and still had it sitting in their office. Not all of them, but many. And I can say with confidence that there is a segment of that population that still likes having something they can hold in their hands and look at.

Several people grabbed the information off their desk, the floor, or wherever it had landed and said, “Yeah, I’ve got your stuff right here.” In some places, my literature had become part of an ever-growing pile of information collected from mailings and trade shows.

But one exchange stood out more than the rest. It happened at a fastener association social event.

“Oh yeah, you sent me an envelope with literature. Just an FYI—I will never read that. You need to email that information to me.”

I wasn’t stunned, but I knew there was a learning opportunity there.

“If you don’t mind me asking, how old are you?”

“25.”

“Interesting. You’re actually about five years younger than my youngest kid. Thanks for the feedback—that’s helpful. There are a lot of young people coming into the fastener industry, and I’m always trying to learn the best way to connect with them.”

Not to be smug, but in the following weeks I had the chance to visit that same company and meet with him and several of his coworkers. Let me just say—the rest of the group (some older than him) ate up the information. They handled the hard-copy brochures with genuine enthusiasm and interest.

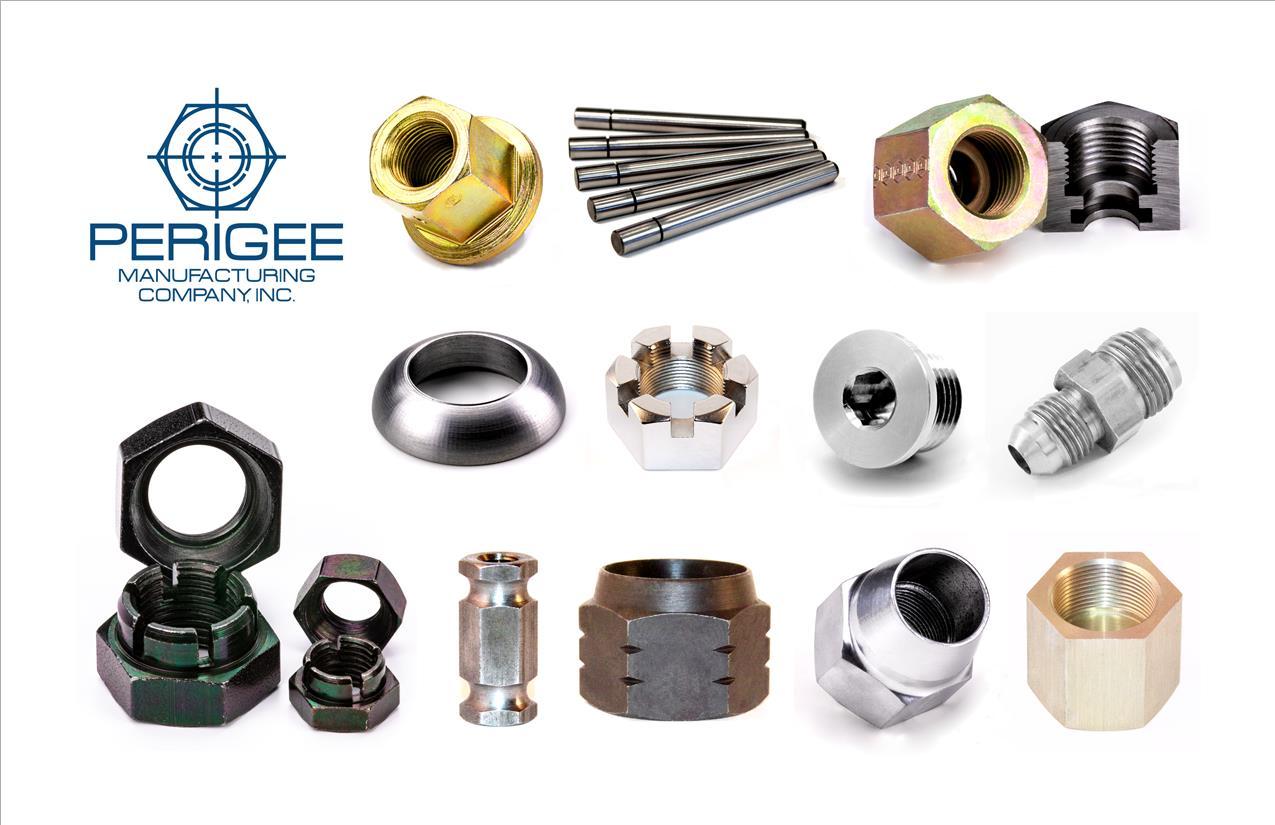

I also brought samples—not exactly something you can email, and in my opinion, far better than pictures.

It turned into a great meeting, and that young man and I have since built what I think is a very solid relationship.

Still, I couldn’t just drop his comment: “Yeah, I’ll never look at that.” (I know I’m paraphrasing a bit—journalistic liberties.)

After that, I made it a habit to ask younger buyers and decision-makers how they prefer to receive information. One question I often ask is:

“How much attention do you pay to companies that bombard you weekly with advertisements?”

I still don’t have a definitive answer. What I do know is that I personally receive a constant flood of information. Unlike my young friend, I might glance at something—but for the most part, I’m a delete-and-move-on kind of guy. Something really has to catch my attention for me to dig deeper.

I’m still searching for these answers.

One other thing I learned this past year is to start using ChatGPT. I’m not great at it, but I’m trying. My kids ask ChatGPT about everything, so I decided to ask it a few questions about reaching customers and decision-makers. Below are a few of the questions I asked and an edited version of the responses.

What Usually Happens to Solicitation Emails

- Many never reach a human (spam filters)

- Some are opened but skimmed—if the subject line looks relevant or personal, recipients scan for 3–5 seconds

- Decision-makers rarely read cold solicitations unless they are highly targeted

- Lower-level or administrative staff read them more often and may forward them if the message is relevant and low-risk

When Businesses Do Read Them

Odds improve when an email is:

- Highly specific

- Short (3–6 sentences max)

- Non-salesy (no hype, no pressure, no “just checking in”)

- Clearly beneficial (saves time, reduces cost, solves a pain point)

- Sent from a real person

Typical Open & Response Rates (Realistic)

- Open rate: 15–30%

- Read beyond first few lines: 5–10%

- Actual replies: 0.5–3%

So, in the end, I sent this young gentleman the information he requested. He did read it and responded and all worked out well. And, per the recommendations of Chat GPT, it was targeted, specific, potentially very beneficial and – it was from a real person. It hit all the targets.

I do see a lot of advertisements coming in via email blast and, while statistics suggest the hit rate is bad, you only need a few success stories to add a new, potentially lucrative account. Hit rate be damned! Same goes with cold calling or mailing stuff. If you follow the general principles noted above and you’re wasting people’s time, you just might pick up some new business or a new account. Throw everything at the wall, right?

I think my next Chat GPT question will be about LinkedIn effectiveness. Lots of content popping up there and I am sure there are analytics to determine whether something is working. You can often tell when a person or a company is making a concerted effort to increase their LinkedIn content. Sometimes you will also notice when that content dwindles or goes away completely. We’re just all trying to reach out to business partners in an ever-changing world.