TS: First of all, let’s talk about the name JM Tor Par. Please tell us the meaning behind the name.

Jose: When my father, Jose Janeiro, started the company in 1984, he was manufacturing hot forged bolts, cap screws and suspension parts for a Mercedes Benz Trucks plant close to Mexico City as well as for other truck and trailer suppliers such as Fruehauf and Kenworth. Originally, the company was called JabaMet. Jabamet was the abbreviation for his family name (Janeiro Barros) and the word metal, all combined together.

In 1994 JM Tor Par started as another commercial entity and was part of the JM group. At that time, JM Tor Par imported nuts, washers and other complimentary items that they would sell with the bolts that were manufactured in Jabamet. Products were imported from the US, Canada and Asia.

Finally, our brand and the group were being referred to in the market as JM and we decided to put it all together under the JM name. Internally our company now uses the JM Tor Par name for all our activities in the fastener industry.

TS: And today, JM Tor Par is a hot forger. You make hot forged bolts, correct? Tell me more about the types of products you manufacture.

Jose: Yes we are a hot forger, but we like to say that we are not like other hot forgers. We have been recognized in Mexico and now in the US and Canada for being a high quality manufacturer. We manufacture all our parts under cap screw standards and constantly invest in our equipment, infrastructure and in our team in order to be able to offer products for O&G, construction, mining, earth moving, metric specials and heavy duty suspension manufacturers and distributors. And these are just a few of the special industries we work with.

TS: Your company is a family business. How long have you been in business? Can you share with us some of the company history?

Jose: My father started more than 45 years ago in the automotive industry, just when he arrived from Spain. He is a mechanical engineer and has been involved with fasteners for his entire career. JM’s 40th anniversary will be in June 2024. I’ve been involved in the industry for more than 18 years.

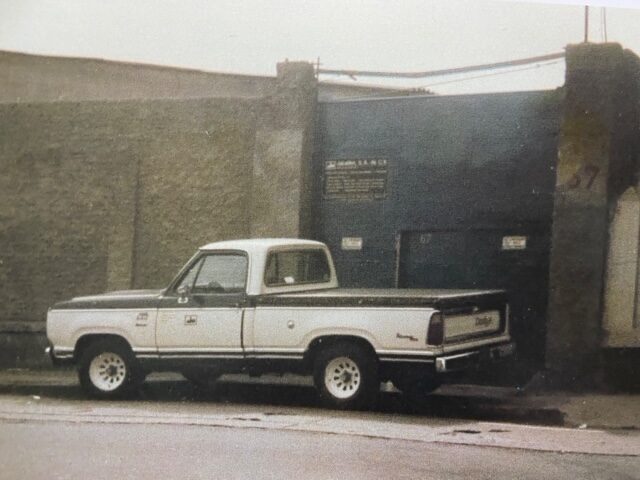

The company started with one forge, one Dodge pick up truck (bought with the proceeds after my father sold his VW Beetle and my mother her Ford Mustang) and it was the family and company’s sole mode of transportation. JM became one of my father’s passions. He would work seven days a week from morning until 11pm at night and his main goal was always doing things the right way and always being able to show people the value of his word and name.

I am one of two siblings. I studied Industrial Engineering in Mexico and Australia and went to live to Taiwan when I finished my degree. I worked in Asia for some time with fastener manufacturers and traders and then came back to Mexico where I spent time working at JM. Next, I went to work at GE for several years. After 2008 when the market and economy crisis erupted all over the world, I came back to JM to start working in exports, imports, and sales. Then finally in 2017 I took over the role directing the operation. About 10 years ago, I completed my MBA in a Mexican University affiliated with Harvard. Part of my studies included trying to understand better the shift our industry was taking toward financial involvement from investment groups and trying to get the best value added into the company.

TS: You manufacture in Mexico. A lot of U.S. distributors and manufacturers have facilities in Mexico so moving product back and forth is not unfamiliar to many U.S. companies. How do you handle the movement of product when you ship outside of Mexico?

Jose: JM directly services our customers as though we were a local supplier in the US. We are part of the USMCA (North American Trade Agreement) and we actually buy our steel in the US. We handle all the import transactions and duties needed to get the product across the border from Mexico to the US. We supply products which are US melt and we ship to our customers in the US and Canada from a warehouse in Texas, so for our customers it is like they are buying from any other US based supplier. We plan to start offering more services during 2024 with a US based local JM office and warehouse which we feel will be even more beneficial to our current and future customers. Right now some people from our administrative team are already located in Texas and constantly visit our local customers.

TS: You are a member of IFI and I believe the only Mexican manufacturer of fasteners that can say that. Tell us a bit about the quality systems that you have in place to meet the specifications of your customers.

Jose: In our group we have three different companies, one which actually supplies product to more than 90% of the automotive brands that manufacture in Mexico. We supply to them through our TIER 1 customers, which require IATF standards and certifications. In JM we also supply to some OEMs through some of our global customers. All the companies within the JM group work under the highest standard of the quality certification that any of our companies have. Even JM is ISO certified, and many of our processes are according to IATF in our group. We receive training directly from the IFI through US programs and in Mexico in our facilities directly conducted by the IFI Technical team. We have the only fastener heat treatment facility in Mexico which is audited to supply to API suppliers in O&G in the US. As you can see, there are many quality considerations we have in our processes that we must follow. Compared to other hot forgers that only supply commercial parts, we feel we meet much more stringent quality standards.

TS: So, in addition to having high quality products, what has been the reason for JM Tor Par’s strong growth and success in the marketplace?

Jose: As mentioned before, we’ve been buying our steel directly from a US supplier and all our material and certificates for raw material are directly supplied by them. We qualify as a North American product and as a US Melt product supplier too. That has been important to our growth outside of Mexico. But really what we consider to be the key to our success is our team and all the people involved in the company, so we are always looking to have a better trained and more professional team. There is always time to learn, to invest, to grow and to be a better version of what we are right now and our goal is to be the best hot forge manufacturer in North America. Not necessarily the biggest, but the hot forger with the best product, service and experience possible. JM is all about making things right in all ways possible.

Note from TS: I have a regular column in Fastener Technology International (FTI) magazine called 10 Minutes with the Traveling Salesman, which can be read online at www.fastenertech.com Subscriptions to FTI, print and digital editions, are free-of-charge for fastener manufacturers, distributors and users as ell as suppliers to the industry.