TS: Let’s take a minute to clear up some confusion I have with your company. I need to clarify if I am talking to Jake from ISSCO or Jake from BTM. Tell me about both companies and what they do.

Jake: Depending on your question, the answer would come from either Jake or possibly both. Does that help clear up your confusion? ISSCO is a wholesale fastener distributor servicing accounts throughout Missouri, Kansas, Iowa and Nebraska. BTM Manufacturing is a domestic manufacturer of threaded and bent wire products, with a focus on per prints items for original equipment manufacturers, industrial suppliers and distribution.

TS: I believe these are family businesses, correct? Tell us a little about the history of the companies.

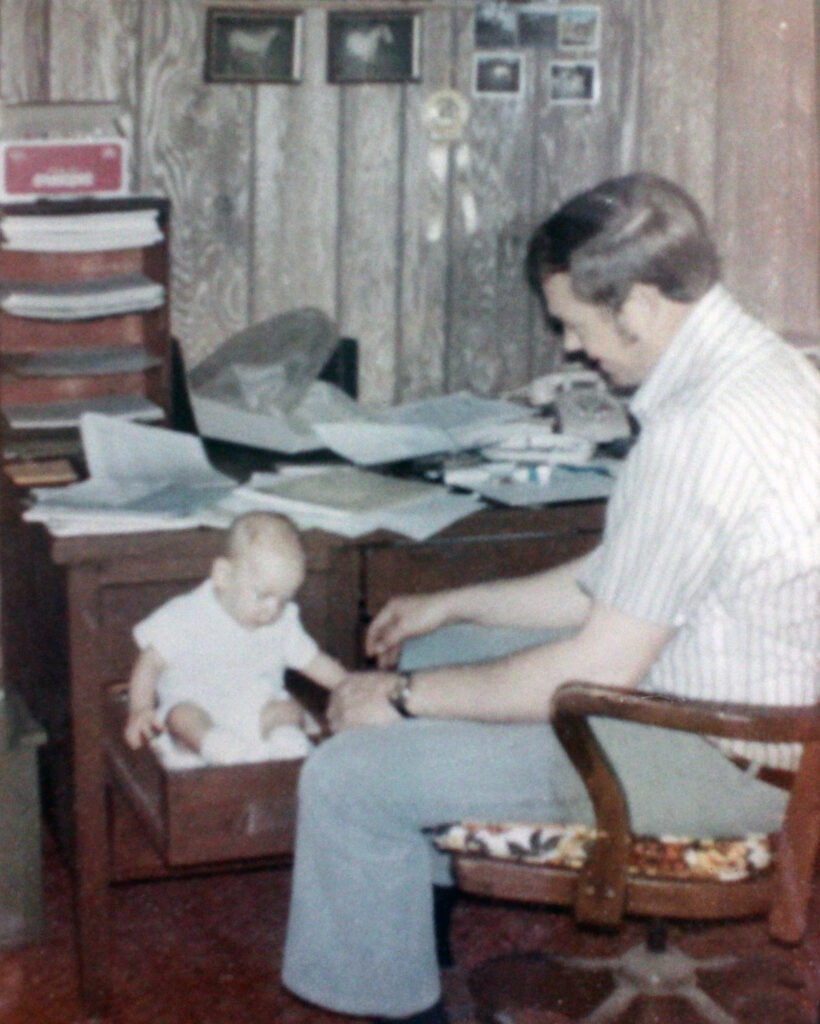

Jake: Yes, my parents started ISSCO out of the basement of our Independence, MO home in 1974. ISSCO has been located in Lee’s Summit, MO since 1986. My father, Joe L. Davis Jr., just recently made the decision to scale back his daily involvement, which means he easily spent over 60 years in the fastener industry. He even met his wife (My Mom) at Kansas City Nut & Bolt! BTM, which stands for Belton Tool & Machine, was started back in the early 1960’s and purchased by ISSCO in 2013. BTM has been an array of different companies (Machine Shop, Fastener Distributor, and Manufacturer) until finally settling as a manufacturer of threaded and bent wire parts. BTM is still located on a retired air base in south Kansas City and shockingly has an abandoned “war” room within our warehouse, complete with maps. It is a bit eerie and really cool at the same time.

TS: You have become involved with a number of fastener associations in the last couple years. Which groups are you involved with now and talk a little about the value you see by being involved with these groups.

Jake: At the moment, I am the Chairman of the Southwestern Fastener Association and was recently voted in as Secretary of the Mid-West Fastener Association. In my attempt to introduce BTM to more of the industry, I thought it made perfect sense to join as many of the fastener associations throughout the country, without spreading myself too thin. Ultimately, I believe the value of each association is the relationships that you are able to form and how you choose to foster those relationships. Keep in mind, you have to be an active participant or you will be hard pressed to find any value in the associations. I met others that were serving and it sounded fun and interesting. This pushed me to want to participate on a more professional level, plus I feel like it goes hand in hand with being in distribution and manufacturing.

TS: You are a distributor and a manufacturer. First on the manufacturing end – what challenges are in store for us in 2021? Material, labor shortage, keeping your workplace healthy. Let’s touch on all those.

Jake: D – All of the above! I am optimistic that things will continue to pick-up for our industry in 2021; however, we are being presented with some challenges right out of the gate based on the current logistics and port situation. BTM has already started receiving price increases in regards to material and plating as we start this New Year. We are constantly looking for employees that we feel will be committed to our culture of service and quality. In my opinion, our country has a major problem on our hands in regards to the widening skills gap when it comes to manufacturing and I would love for our industry to play a role in highlighting just how important these manufacturing jobs are to the longevity and success of all our companies.

TS: This is kind of a strange question Jake, but those are the ones I like asking best. You and I did not know each other until just maybe the last five years. In that short amount of time your name has popped up everywhere. You have done a remarkable job of putting BTM and ISSCO on the fastener industry map. And, I don’t think this was just a fluke, I think you set out to do that? Am I correct in that observation?

Jake: Man I hope people haven’t gotten sick of me already!

I have certainly been intentional when it comes to introducing BTM to more people and the different regions throughout our great country. Before the purchase of BTM, my parents and I would travel to the annual fastener show. Although my Mom was really only interested once it moved to Las Vegas. I have always enjoyed meeting and talking with our suppliers. So, I was excited about the opportunity to be an exhibitor and be on that side of the aisle. It comes back to the relationship and regional association part of our industry. It would have been much tougher to connect without them holding conferences and shows. I feel like my network of fastener friends has grown and I truly believe that has benefited BTM, ISSCO, and me personally.

TS: Which is easier/harder – manufacturing or distribution?

Jake: They both have their challenges, that is for sure. Ultimately both require us to meet or exceed the expectations of our customer base. I feel like manufacturing has more of a set lead time due to the manufacturing process, whereas distribution is driven by having inventory and replacing it in a timely fashion. One of my goals, when we purchased BTM was to add a level of service to what we did on a daily basis. That’s not to say it was not already happening; however, I wanted to step up our game based on our experience of being a fastener distributor for 46 years. I like to say that BTM is a service minded manufacturer!

TS: What are a few things about Jake that we do not know that you’re willing to share?

Jake: TS, you know no one likes to talk about themselves! I am actually somewhat of a shy person until I get to know someone. Introducing BTM at different associations and shows has actually helped me break out of that a little bit. I love to reminisce, with my high school, college and industry friends. I have run 3 half marathons with the most recent one being in October 2019. During each race, I always questioned what in the hell I am doing! Also, I do enjoy donating platelets at the Community Blood Center and would encourage everyone to sign-up and donate if they are willing and able. Finally, one of my best friends was my Mom, and I was grateful to have worked with her until she passed away in July 2000. Let’s all try and make the most of the time that we have together!

TS: BTM coffee is now a trade show staple. How’d you come up with that and is there a special blend that you have?

Jake: I happened to be having a conversation with a friend who owned a small coffee shop in Kansas City. I was explaining the trade show opportunities coming up for BTM and my desire to find something completely different to promote our company. He suggested coffee, as he had been roasting it in small batches for his own shop. I was intrigued, so we scheduled a “coffee cupping”, which was basically a taste test. I had narrowed it down to a couple of choices, so we actually combined them to create our U-Bolt Blend coffee. It’s been a lot of fun and I truly appreciate the support of the industry and our friends over at Fully Threaded Radio. The most important part of our U-Bolt Blend coffee is the mission of our local roaster here in Kansas City, which you can find online at Eleos Coffee (www.eleoscoffee.com). It’s a great partnership and we are looking forward to getting back out there to share our coffee with everyone.