This was my first attempt at a two person interview and I couldn’t think of a better team to do it with. Jason Wagner and Ilian Dimitrov are respectively the Executive VP and General Manager of The Richard Manno Co. While The Richard Manno Co. has been around for many years, Jason and Ilian are the current management team and have been instrumental in taking the company “to the next level”.

The company was founded by Richard Manno in 1978 and sold to current owner, Vincent J. Manno in 2004. Richard eventually retired in 2009 and the company has continued to grow under the management team of Jason and Ilian. Through continuous improvements in their processes and investments in new facilities, equipment & personnel, the company continues to make every effort to “exceed customer expectations”. The Richard Manno Company is an ISO 9001:2015 and AS 9100 Rev D certified manufacturer. They are ITAR Registered as well as a QSLM/QSLD Class 2 government approved supplier.

TS: You two are “guiding the ship” at Richard Manno & Company. How long have you two been working together and how did you end up at the company?

Jason: Ilian and I have both been with the company for over 9 years. I came from a finance background and Ilian was in print media.

TS: Ilian, you are from Bulgaria. How did you end up in the U.S. and then specifically in NY at Manno?

Ilian: I was second year in college in Bulgaria, when a friend of mine asked me to go with him to an interview for students who wanted to study abroad. The interview was organized by Ohio State University. I decided to give it a shot and actually got picked right away. A month later I was in the USA starting a new chapter of my life. I completed my internship in Ohio and moved to New Jersey where I graduated from Montclair State University with a major in Business. A few years later I got an opportunity to join the Richard Manno Company. I didn’t hesitate because I always enjoyed manufacturing. I went to high school which specialized in CNC programing and also worked for my uncle’s machine shop. RMC was a perfect fit for me and I finally realize why they say people who work in this industry always stay in it.

TS: So, in the last few years you guys have been responsible for re-inventing the Richard Manno Co. You’ve essentially recreated the company. Tell me about some of the changes that have taken place over the last several years.

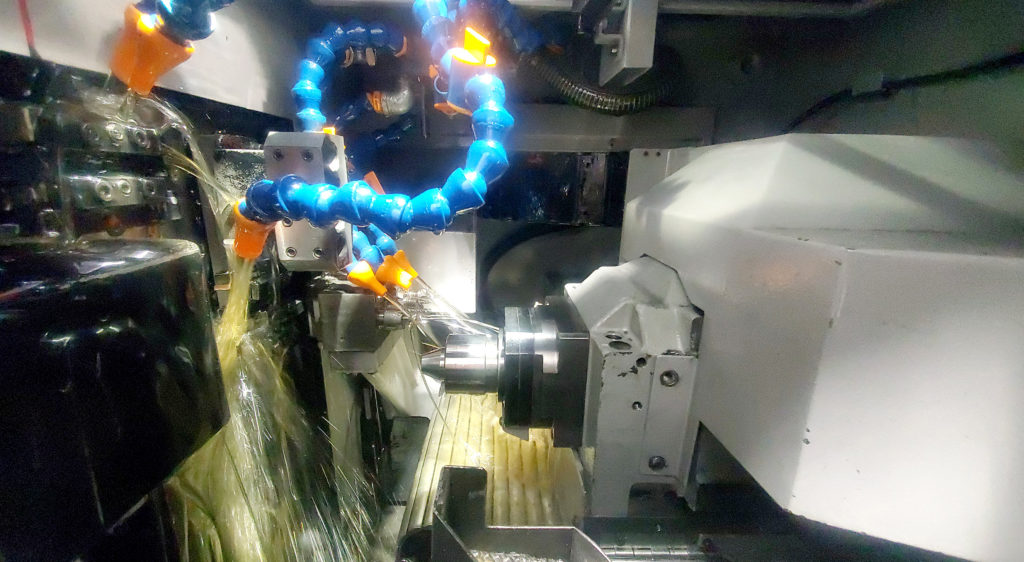

Jason: While Richard Manno Co remains a stocking manufacturer for large catalog houses, up until mid-2014 we were just a job shop for spot buys and small runs on per print items. At that point we had nearly 150 machines but did not have any CNC Swiss Lathes. We knew that in order to be competitive on long running high volume jobs as well as intricate Aerospace, Medical and Military parts we needed to move into CNC Swiss machining. In 2014 we purchased our first 2 of these machines. In 2016 we purchased another building and expanded our CNC Swiss, CNC Lathe and Escomatic departments. By the end of 2019 we maxed out the capacity of that building and started replacing some of the older equipment at our original location with CNC Swiss machines in order to continue our growth in that area. During this process we have maintained our QSLM Class 2 approval, ITAR Registration and transitioned from ISO9001:2008 to AS9100 REV D in 2018.

TS: In the past people might have thought “electronic hardware” when they thought of the Richard Manno Co. What new market segments are you targeting? Where are you seeing your biggest growth? What kinds of parts are you making today that maybe you did not make in the past?

Ilian: The areas that we are targeting are Aerospace, Military and Medical with our biggest growth being in Aerospace. Some of the parts that we have made in the past would have required numerous secondary operations, most of which had to be completed one piece at a time. With our investment in equipment and personnel, we can drop those parts complete or near complete which makes us competitive on higher volume runs. We can be the source for prototypes, mid-size runs and long runs from commercial parts to tight tolerance precision components. Not only did we expand our capacity in terms of production volume we are now able to produce parts with features that we were not capable of producing in the past.

TS: You still stock product for stock and release programs. What kinds of parts do you have in stock for someone looking to just buy product from your inventory?

llian: We stock shoulder screw, dowel pins, thumb screws, thumb nuts, captive panel screws, spacers and standoffs in a variety of materials and finishes some of which are certified to Military and Aerospace Standards.

TS: The commitment to become AS 9100 certified is substantial. There is a large investment of time and resources to achieve that certification. Why did you go after it? Did you have business you knew you could go after with AS 9100 certification? Did your customer base request it of you?

Jason: This decision was customer driven as we had numerous requests from various customers to become certified. By becoming certified it has opened up additional opportunities with existing customers as well as with new customers. Simply put, there were parts that we couldn’t produce without it.

TS: The Richard Manno Co. has been in business for many years. What business trends do you see affecting Manno and affecting the fastener industry in general?

Ilian & Jason: Automation, overseas pressure, and cost and availability of skilled labor.

TS: Look into your crystal ball and tell me what you see for the Richard Manno Co. in the next several years?

Jason: Growth through re-investment in the company and continuous improvement.

TS: What is one thing about the Manno Co. do you think would surprise people who think they know the Manno Co.?

Ilian: We stock over 6,000 different SKU’s. Not too many manufacturers stock as much as we do. While we are not a huge company, a lot of people do not realize how much benefit there is to doing business with us.

Note from TS:

I have a regular column in Fastener Technology International (FTI) magazine, called 10 Minutes with the Travelling Salesman, which can be read online at www.fastenertech.com. Subscriptions to FTI, print and digital editions, are free-of-charge for fastener manufacturers, distributors and users as well as suppliers to the industry.”

Our most recent inductee into the FASTENER HALL OF FAME shows why he was deserving of that award.

Great 10 min interviews that are packed with information that always informs the reader with new and interesting facts !!

Thank you TS for another eye opening article. My perception of RMC has been, until now, of the pre-2014 company. It is always great to see product being made in the US.