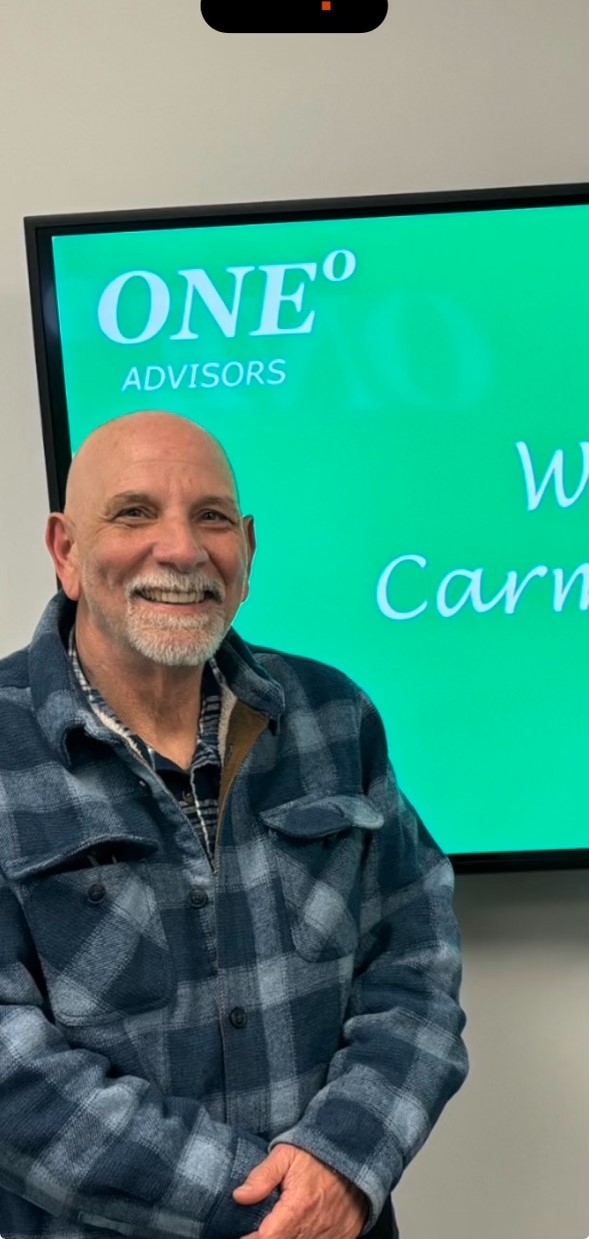

TS: Carmen Vertullo, so much has already been written about you, where do I begin? You won the prestigious NFDA Fastener Professional of the Year for 2023, and the NFDA published a thorough and very well-done biography of you and your many accomplishments. I encourage readers to track down that announcement if they want to find out more about your personal background and accomplishments.

https://www.nfda-fastener.org/fastener-professional-of-the-year

To repeat all the details here would take up a lot of space and not leave room for me to ask you about what is new and exciting with Carmen.

Carmen Vertullo (CV): I would just like to add one detail about the award – it was one of the most pleasant experiences of my professional life – I would like to say I humbly accepted it and did not deserve it – but I had a change of attitude – I am very happy and proud to have been selected. Humility is overrated – you can’t brag about it.

TS: So, I had met you before but got to know you better when you were one of the instructors for the Fastener Training Institute’s (FTI) Fastener Week in Cleveland several years ago. You were one of my instructors. And, among your many accomplishments, you were a founding instructor for the FTI’s Certified Fastener Specialist (CFS) fastener training program.

So, let’s begin there. How many different training organizations or seminars are you, or have you been involved with?

CV: Going back to my beginning in the industry with Ababa Bolt in the early 1990’s I developed and presented training programs for our OEM customers and local trade shows. Then the LAFA (Los Angeles Fastener Association) which later merged with the WAFD (Western Association of Fastener Distributors) to become PACWEST Fastener Association developed the CFS (Certified Fastener Specialist) training program, which now is presented by FTI (Fastener Training Institute). I anchored that program with my wonderful late great mentors Joe Greenslade and Bengt Blendulf for 10 or so years, Then Salim Brahimi and Laurence Clause came along side and they do all the heavy lifting now – I still show up occasionally. I would estimate we have trained well over 1000 fastener professionals in that program over about 30 years – ask Jo Morris for the exact number. I have done hundreds of webinars for FTI and my clients, numerous trade show and conference presentations. We have done Fastner Training programs at our Carver Labs training facility in San Diego and have some new ones coming on line in 2024. And of course, over 100 episodes of The Fastener Training Minute on Fully Threaded Radio. Eric Dudas is a great inspiration to me in many ways – not just fasteners. My favorite though is our Fastener Experts Mentoring program. Its me and about 20 industry pros who want to sharpen their fastener expertise. We meet on ZOOM twice a month for an hour or so. I loved it!

Of course, we are members of many organizations that we may not provide training directly to– ASTM, IFI, ASME, ISO, RCSC, AISC, SAE, etc. I have to say that I owe a great deal of gratitude to FTI for my industry presence.

TS: I believe you have a degree in manufacturing engineering but how did you first become involved in the fastener industry?

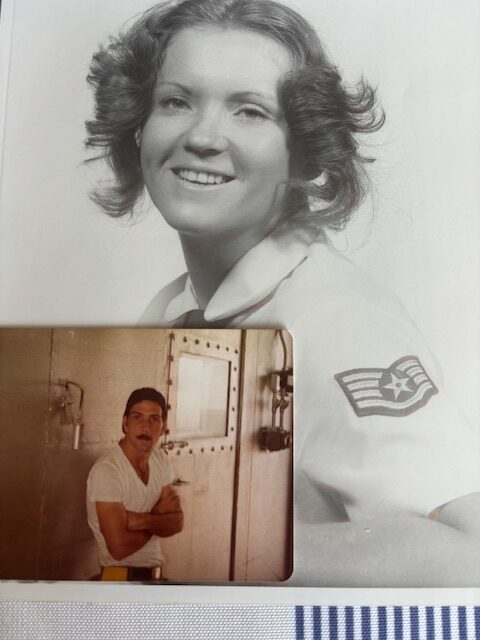

CV: After leaving the US Air Force in 1980 I worked in a turbine engine research test cell here in San Diego. I ran a jet engine test cell in the air force so that’s where my background in testing started, but both of those jobs also required a strong understanding of fasteners and I got some pretty good fastener training in the Air Force. I then had a job designing and building test equipment for the Tomahawk Cruise Missile. When that program left San Diego, I needed a job and went to work as a sales manager for Ababa Bolt. I like to say I knew nothing about sales, nothing about management and enough about fasteners to be dangerous. I was there for 10 years but morphed from sales to quality and process improvement – that is where I guess I became a fastener expert.

TS: Fastener quality is not just how you test products. I have heard you talk about how quality systems have to start with some very simple procedures, like how companies procure the raw materials, all the way to final inspection and testing. Is our industry getting any better at implementing these types of systems?

CV: Our industry is outstanding at implementing these types of systems. As a consultant I get to see the inner workings of a lot of different fastener companies across the supply chain, as well as their customers. Manufacturers, Importers, Distributors and dabblers. Its rare to find a company that does not have a registered QMS or is at least working towards that today. I am very proud – and humbled – that the training we have provided over the years has driven the industry in that direction.

TS: What is your biggest concern about fastener designing, engineering and applications where fasteners are used?

CV: We are losing fastener industry talent and expertise faster than we can replace it. That’s one reason for my Fastener Experts Mentoring Program. Fastener technology is not taught in engineering programs at colleges and universities. We see the same old mistakes being made that we thought were trained out years ago – especially- believe it or not – hydrogen embrittlement failures – its not going away and it should be.

TS: As a regular guest on Fully Threaded Radio, you have brought a lot of attention to hydrogen embrittlement. I would go as far as to say you are kind of the “hydrogen embrittlement guy” partly because I think Eric Dudas loves saying that phrase. Is it as rampant of a problem as it seems?

CV: It’s not rampant – its not an alarm bell safety issue, but we still see our industry getting in a lot of trouble over it. Trouble means costly failures and law suits. I would much rather spend time and money on implementing a good HE risk-management program for a client than conducting a failure investigation – or God forbid being the expert witness in a legal action.

TS: We have IFI standards that govern a lot of how fasteners are made and used but a lot of knowledgeable people are retiring and with them goes a wealth of knowledge. Should we have concerns moving forward?

CV: YES, we should be concerned. There are a lot of fastener standards organizations and I participate in all of them. We need to pull more young people into them. If you are a fastener business owner or executive, I strongly encourage you to incentivize your people’s participation in these organizations. Don’t just pay their way – pay them extra. Recognize them for their initiative and contribution to the industry. It is financial and time commitment, but worth much, much more than the expense. Plus, its great fun and fellowship and keeps you tied to the industry.

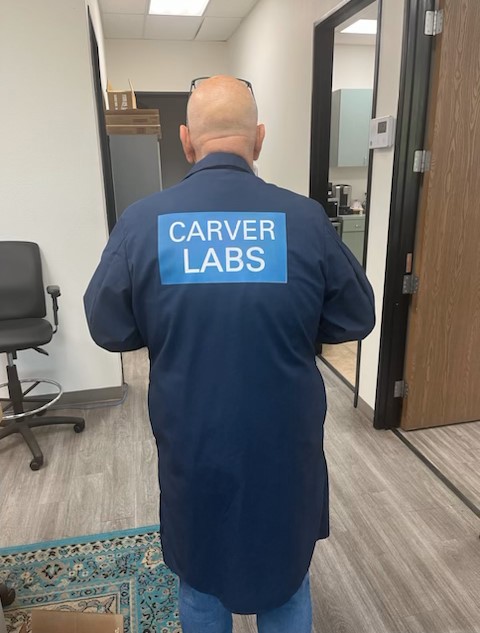

TS: Despite all of your numerous accomplishments, you do not seem to like to sit still. Instead of resting on your laurels as the incumbent NFDA Fastener Professional of the Year, you are creating a new business which includes things like fastener application consulting, testing, training. And, you have some manufacturing that you do. So, please give us the rundown of your current operation and what all you are doing!

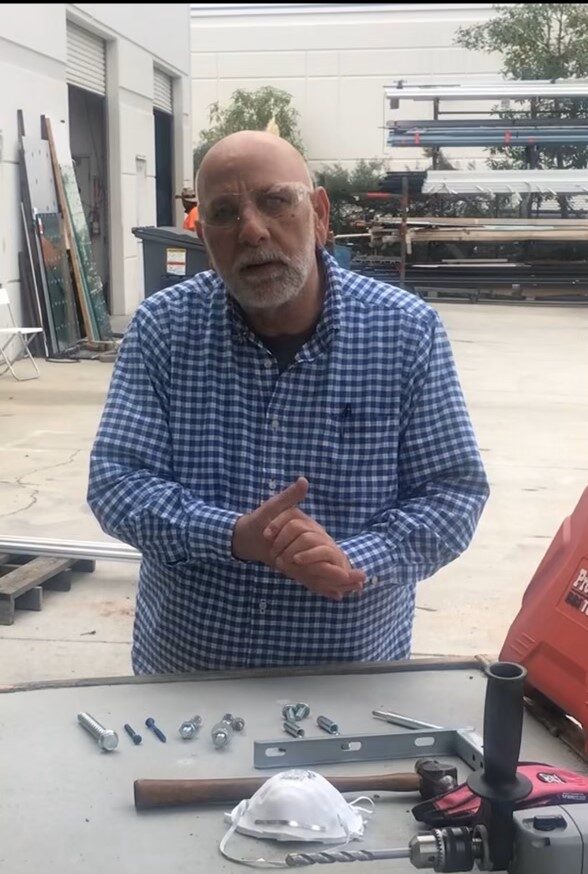

CV: Carver Labs is the newest part of our business- not exactly new. Lois and I have been doing the fastener consulting, testing and training thing for over 25 years. We are really excited about Carver Labs though. It’s a combination of 13 different fastener testing laboratories – there’s no fastener test we can’t do and if there is one, we can’t do we find a partner to help us out. We are often the expert between our clients and other labs.

On the manufacturing side have a CNC machine and welding shop. We design and manufacture special fasteners from scratch, which includes engineering, drawing and testing. We also modify off-the-shelf fasteners to customer needs. We have a 4 KW CNC fiber laser cutter where we make special washers and flat or bent parts too difficult or not cost effective for stamping. We make sophisticated test fixtures, tooling, and research specimens for our clients, our partner labs and for in-house use.

Our two reps (that’s a technical term, but they are just really good friends) Doug Weiland in the west and Jackie Ventura in the east, have been an absolute godsend. And we have the blessing of people like you TS – promoting and helping us out with your time and industry experience.

Check us out at www.carverem.com or on LinkedIn.

TS: Is there anything else you still want to do in your career?

CV: Well – I have had a great career in the fastener industry – but there is plenty left to do. I have several product development projects in the works. Some are fasteners and some are not. I want to write a book – not necessarily about fasteners.

TS: Tell us something else about Carmen Vertullo that we do not already know.

CV: If you know me already, then you know the most important thing to know about me is my love for Jesus and his church. I can give full credit to Jesus for any success I have enjoyed in this business. Also, for my family – two great well-launched kids, Rob and Teri, and 47 years of marriage to the best woman ever. We have 6 grand kids and a great extended family. I ask your prayers over all of us – especially Rob who is serving as an army combat medic and first sergeant in Syria.

I love smoking meat. I enjoy the occasional cigar and have just started getting familiar with firearms. I love my work and I love my not work.

I really enjoy the fastener industry events – trade shows, mud runs, bed builds, pool parties, fastener bashes, socials and celebrations of all kinds. If you are reading this, I hope you know I love hanging out with you too!

Some of Carmen’s adoring fans – actually, individuals who were extremely grateful for his assistance and instruction

TS, Great article on a great friend. If you have spent any time with Carmen, you are friends. We are blessed he shares his knowledge with the rest of us, we just need more people that want to learn and learn you will with Carmen.