TS: You are an accountant by trade. How the heck did you get yourself so deep into the fastener industry in what seems like a short amount of time? You have served as president of MWFA and been on the FIC board for years. How did all this happen to the company accountant?

Bob: Well, it really does all stem back to being an Accountant. I started with Abbott-Interfast as Controller 29 years ago when there were 3 generations of Binders (owners) alive and working daily in the business. My office was right smack in the middle of them and of course they all had different needs so I quickly learned to adapt. I really dove into the numbers in my first few years and apparently my accounting skills impressed them enough to promote me into the meat and potatoes of the business – namely Purchasing and Manufacturing. I started attending local trade shows, seminars and industry events. I took my first fastener class with the MWFA in ‘95, was impressed and just kept going (that is also where I first met my good friend Rich Cavoto who taught the Metric portion of the class). After attending MWFA events and shows for many years, I decided I should give back to the industry, so I ran for the BOD in 2005 and have been involved ever since. In 2014 the MWFA needed to replace its representative to the Fastener Industry Coalition (FIC) and I volunteered. Again, met more great folks who also volunteered for the FIC. In 2018 the Fastener Training Institute asked me to join their board as well. Ditto! I have met a lot of great people in our industry and have made many close friends since making the switch, I guess I never realized how restricted I was just sitting in a room keeping score.

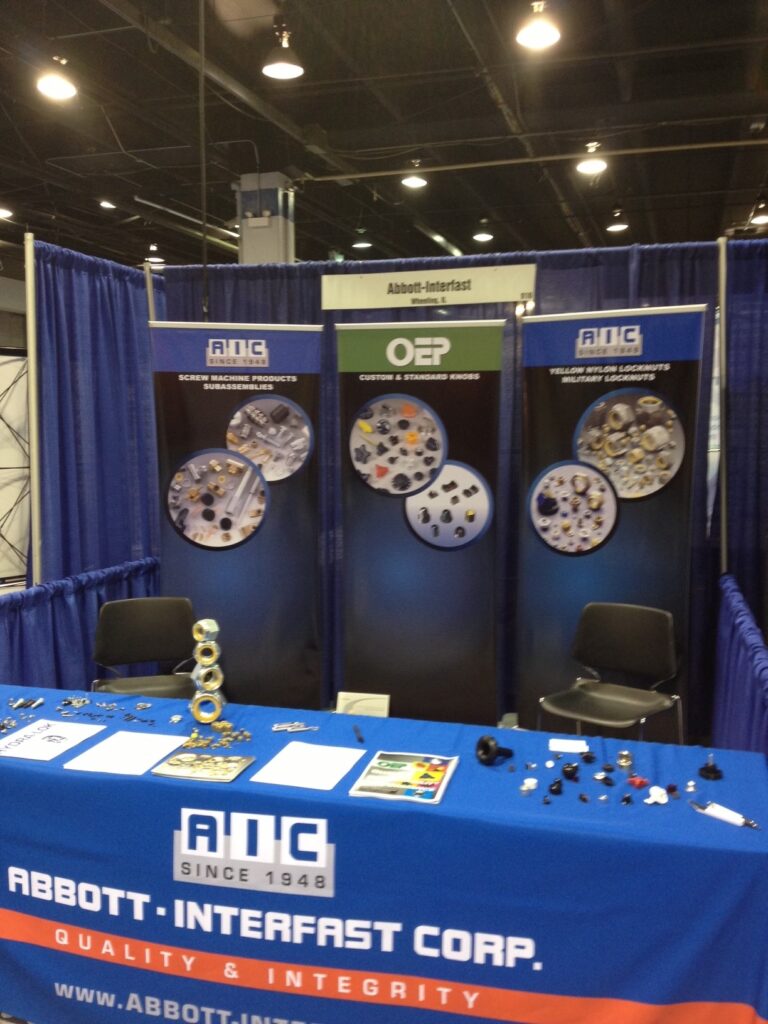

TS: Let’s talk about Abbott-Interfast. My early industry memory was that Abbott was a supplier of nylon insert locknuts with the yellow ring. Back in the days of the Columbus Fastener Show, there was about 5 players that all had different colored nylon inserts and Abbott’s was yellow. But, as I have learned, that is a small part of what Abbott does. Fill me in on the other business units.

Bob: When I started with Abbott-Interfast there were over 20 different companies to “account” for monthly ranging from fasteners to a restaurant. The Binders were very diverse in their business ventures. Over the years we scaled down to core fastener business units. In addition to Abbott, we have a knob division – OEP LLC and a deck screw company – Titan Metal Werks, which sells branded High Performance (SplitStop™) and private labeled deck screws for wood and composite boards. Abbott also started and still maintains The Nationwide Fastener Directory™, although nowadays the listings are on our website which also features our popular but now virtually printed 2 volume book. Our manufacturing company, Abbott Metal Werks, makes locknuts, precision screw machined products, CNC parts and assemblies. Abbott sources from all over the world and backs it up with domestic manufacturing, whether it be our own shops or local manufacturers. Over the years, Abbott has secured many patents and we continue to innovate but since most of our business is OEM direct, the industry doesn’t always hear about it.

TS: Part of your company belongs in the STAFDA market, part of it belongs in Aerospace, part at the OEM and part at the distributor marketplace. That is some really good diversification. Did that just develop that way or was that diversification intentional?

Bob: Abbott-Interfast has always been diverse. The goal was and still is, to some extent, to not have many customers or industries greater than 3% of our business. Of course, these days, we welcome rapid growth when one of our customers take off. That philosophy has been key to our 73 year survival and success as a small manufacturer competing in a country where so much product is now outsourced internationally. Historically, our business has not jumped quickly with the rest of the market, but also doesn’t drop when things slow. Steady slow growth has been our formula.

TS: You are also a manufacturer. What products do you manufacture at Abbott-Interfast?

Bob: We do make some fasteners, but we really focus on precision parts to prints, aka specials. We also manufacture knobs, many standard, both metal and plastic, but again focus on the specials. Assemblies are a big part of OEM work, and we manufacture many of them in our own shops. We welcome tough parts, it’s our wheelhouse and it helps us learn. Every special has its own quality and inspection requirements, manufacturing method and of course unique application. And as we know, they rarely come with perfect instructions, each one has its own story.

TS: During 2020, I’d be remiss if I did not ask how COVID-19 has affected your business. How has it affected you guys and what have you learned?

Bob: Well the first thing we learned is that we weren’t prepared to immediately shift into working from home. There was some portability, but employees had to use their home computers and that had security issues. We quickly adjusted, didn’t hesitate, made the IT investment and geared up for transition. Our work schedules were changed, we spread out those remaining in the office, added air purifiers, self-temperature checking stations, disposable gloves, etc. We discovered pretty quickly which of our industries were or were not fail-safe from Covid, either brought in extra inventory early or delayed product not manufactured yet. Finally, we called all of our major accounts regularly and kept a weekly log of customer plant closings, openings and expedited or delayed shipments. The file was accessible by all departments and it helped us prioritize. Communication was key, talking with customers and staff. There was also a rapid learning curve to balance holding inventory for customers, letting your A/R age and keeping current with suppliers, all while still making payroll, rent, etc. and while we had been through downturns in the past, this was totally new and came out of nowhere.

TS: What is next for Abbott Interfast? What do the next 5-10 year look like?

Bob: Our #1 priority is continued growth with additional machining capabilities, we recently bought another CNC machine with additional ones planned. Online marketing and/or digital marketplace is also going to be our focus for next 5 years. Things are changing so fast, not sure about 10 years from now, except that maybe I will pass the torch by then. While I am not yet eligible for Social Security benefits, I am getting up there in age 😉

TS: On a personal note, you get some good natured teasing about being Mr. GQ. In your defense, you do take care of yourself and dress professionally which sometimes in our industry stands out. Not everyone wears a suit to the Vega show! So first, let’s talk about your training regiment because that is important to you. You’ve done Tough Mudder races and are diligent about taking care of yourself

Bob: Yes, always felt that it’s better to be overdressed rather than the opposite. Eric Dudas first tagged me with the name on a podcast and it stuck, but it’s OK, I take it as a compliment. We have plenty of others in our industry, who like to dress for success, so I am definitely not alone. I was fortunate as a young man to start my career with Florsheim Shoes, and as an employee, was able to buy Royal Imperial wing tips for just $20. At the same time, my Mom worked for Hart Schaffner Marx so purchasing a 3 piece suit for $60 was a regular occurrence. So I was a bit spoiled and it became normal to always wear a suit and nice shoes to work which I did so every day up until about 10 years ago when Business Casual became a thing and then fully integrated itself into the business world. I can talk about fitness for hours, but my workout is not rocket science, just mix it up. I’ve always been fortunate to stay active and lean but like many, I got away from it, especially after having kids. Then, at age 43, picking up a 2 year old daily was killing my back so I started back to the gym and swimming again. I discovered Triathlons, Mud races, various different Obstacle races and fell in love with the physical challenges. The diverse training necessary to complete them, without dying on the course, has kept me in shape and feeling young. Also, I had to keep up with my 3 growing boys/men. I’ve done many races, with my boys too, and still enjoy doing them. My bride and I regularly bike together, I am really slow at running, but swimming has always been my “go-to” for stress relief and I still swim 2-3 days a week. In 2007 I swam from Alcatraz to the beach at Crissy Field near the Golden Gate Bridge – my claim to fame and a lifelong goal. I would love to get an Industry Tough Mudder Team together for those of you interested, when they allow races again. I think it would be a lot of fun.

TS: You also are a die hard Chicago White Sox fan. I had the opportunity to attend a Sox game with you once and was surprised to learn that pretty much your front yard as a kid was Comisky Park.

Bob: Yes, I grew up right between Chinatown and Comisky, a very short walk to the park. We really couldn’t afford tickets but a friend and I got to know the Players Parking Lot attendant pretty well. We used to sweep the parking lot for him regularly and he would let us in free after the 7th inning stretch, so I attended a lot of 2 ½ inning Sox games. Growing up a Sox fan in my neighborhood also meant disliking the Cubs, a trait which I passed on to my kids.

TS: I love that. First, it is important that we raise our children the right way. And getting into games with a couple innings left – that’s awesome! You are a true fan. Ok, changing the topic here – how many watches do you own?

Bob: Best guess, somewhere between 25-30, including a few running & workout watches. It’s a Baer family male trait, my Dad was the same way, and my two brothers both have way more than me. When you’re dressed, a nice watch is as important as your shoes. Now I wear an Apple watch frequently for its functionality and convenience and definitely miss wearing my nice ones regularly. As a gadget guy, it’s a tough trade off.

TS: Lastly, what trends do you see in the fastener industry? Where are we headed with consolidation, innovation and all of the above?

Wow, that’s always a tough question. Acquisitions never seems to rest, so it’s a safe bet they will continue. But many baby boomers retired or are retiring and therefore selling out, so over the next 10 years I think consolidation may slow. Technology seems to consistently move at light speed and almost every large fastener company now has a web presence and E-commerce on their own website. Automated unmanned warehouses I think will be a phase in the future. I really do hate predictions, despite being a numbers person, so I will just make one – AI is growing so rapidly in the background and when it surfaces mainstream, things will change even faster than we can imagine.

Great Story, I’ve known Bob for over 40 Years. He’d be working days, while finishing up his Degree at night. He Always Put Family First, even at a young age, when he was the oldest sibling in the house. He watched over his younger brother and sisters, and helped his Mother, even while balancing work & school. When he got married and started having children, he focused on work, family, and getting his boys involved in sports. Bob’s Plate is always full, but he manages time very well, and he’s able to get everything accomplished. He’s always Learning, and Advancing at Work to make things Better for Everyone Around Him.

Congratulations Bob on all your accomplishments, and giving back to your Industry.

[…] January 4, 2021 / travelingsalesman / 2 Comments […]

TS, A great intertview with a true Fastener Industry icon. Bob not only dresses like a gentleman, he is a true gentleman. Bob believes in giving back to an industry that has given him so muuch. More people need to be like Bob. He has studied his industry. Far too many people stop learning about and seeking knowledge about the industry that they choose to work in, once they have chosen that field. Not so with Bob.

Great read !!!

Loved the pictures