TS: First of all, thank you for taking me on a tour of your facility. There is a lot of history here. And it’s kind of funny to me that you are located in the town right next to where my home and office are located. We’re neighbors.

I could not help but notice old brochures and signage that showed some of the Seaway Bolt history. And that seems like a great place to start. Tell me about the history of Seaway Bolt.

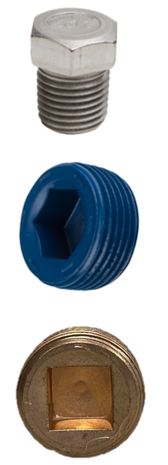

Genevieve Gurnick-Long: Seaway Bolt & Specials was founded in 1957 by my grandfather, Raymond S. Gurnick, and a partner, with the idea to make ladder bolts. Due to a price war on ladder bolts, they quickly had to pivot into other product lines. With the open die headers that they had, they started producing long length specialty bolts and taper thread pipe plugs which has grown to be our core product line.

TS: I felt kind of funny getting a tour of the facility when your dad, Raymond L. Gurnick was not in the building. He has invited me to visit numerous times and I happened to pick the time when he was not there. I’ll come back again when he’s here just so I don’t feel guilty!

But you are here at Seaway and are the third generation to be involved. But you were not just a kid coming out of college when you started. Share with us your path that led you to working at Seaway Bolt.

Genevieve: Gosh it seems so long ago. When I got out of college I applied for over 75 jobs with only a few responses, mostly letting me know I needed more experience. With bills to be paid I asked my father if I could work at Seaway. He of course let me work at Seaway on a few conditions. First he told me that I was going to have to work twice as hard as anyone else, and that if I did anything out of line my head was on the chopping block. With these conditions in the back of my mind, I started as a quality technician learning as much as possible from some incredible ladies, who helped set me up to become the Quality Manager and help lead a culture change as a wave of retirements hit. Like many young people I questioned if this was really what I wanted to do the rest of my life. So, I decided to explore some other options. I did not want to regret not exploring other options so, fully embracing my quarter life crisis, I joined the Army Reserve. It was one of the best choices I made for myself as it humbled me, taught me, and instilled greater confidence in myself. After my mandatory time and an officer’s cap in hand I asked my father if there was still a place for me at Seaway. I’ve been back full time since 2020 working whatever job needs to be done, from tool room, to shipping, learning to setup a header, and how to sell our products. Working for the family business has taught me more than I could ever imagined, and it has helped me grow to appreciate my father, and Grandfather’s hard work and sacrifices as well as the hard work of all our employees.

TS: One thing that really stood out to me was the amount of inventory you carry. Both finished goods and semi-finished goods. Honestly, the amount of inventory was impressive.

Genevieve: What can I say? We are committed to selling the worlds’ standard of tapered thread pipe plugs with 99.5%+ on time shipments!

TS: Your company is another great example of domestic manufacturing in the US. And now there are tariffs. And although tariffs are supposed to affect imported goods it still affects domestic manufacturing indirectly. How are the tariffs affecting Seaway Bolt?

Genevieve: I think Seaway is in the same boat as other small metal manufacturers. We have seen some glimmer of hope with on shoring quotes but nothing has materialized yet. And like all manufacturers who use CHQ wire in the North America market, we’re struggling with the highest cost wire in the world. . So I think we’re probably like most companies, just taking it one day at a time.

TS: So, currently, we have a great company history and a robust thriving business. What does the future look like for Seaway Bolt.

Genevieve: Ohhh the future! I can’t wait. Seaway is doubling down on our engineering, looking to solve problems for our customers. Innovating and finding new ways to make products. I don’t want to babble too much, but we continue to add new machinery and capacity. But, rest assure, as the future arrives Seaway is ready, and committed to our fittings product line, our on time deliveries, and engineering solutions for our customers.

I have a regular column in Fastener Technology International (FTI) magazine, called 10 Minutes with the Traveling Salesman, which can be read online at www.fastenertech.com. Subscriptions to FTI, print and digital editions, are free-of-charge for fastener manufacturers, distributors and users as well as suppliers to the industry.”